Авг . 04, 2025 01:40 Back to list

Eco-Friendly Wooden Tricycle for Kids - Safe & Durable Ride

Explore the next generation of wooden tricycle for kids and advanced tricycle solutions: design innovations, materials, specs, custom options, and real-world applications.

1. Industry Overview: Wooden Tricycle for Kids Market Trends

The wooden tricycle for kids market is undergoing dynamic changes as parents demand eco-friendly, safe, and innovative mobility solutions. According to Global Toy Market reports (2023), the global kids tricycle segment experienced a CAGR of 6.2%, with premium materials like birch, beech, and aluminium alloy finding increasing preference, especially in tricycle bikes for kids designed for both urban and suburban environments.

- Eco-friendliness: Demand for sustainable and recyclable tricycle materials.

- Safety Certification: Compliance with ISO 8124, ASTM F963.

- Expanded Age Ranges: Products targeting kids tricycle 3+ years and even bigger kids (>7 years).

- Multi-functionality: Convertible designs (tricycle car for kids, tricycle motorcycles).

Key Product Segments

| Segment | Key Features | Age Range |

|---|---|---|

| wooden tricycle for kids | Eco-friendly wood, classic design, non-toxic paint | 1.5–4 years |

| Tricycle for bigger kids | Steel/alloy frame, advanced braking, larger wheels | 4–9 years |

| Tricycle car for kids | Enclosed cabin, car-like steering | 3–6 years |

| Kids tricycle motorcycle | Motorcycle styling, sporty frames | 3–8 years |

2. Technical Specification Table: Core Parameters of wooden tricycle for kids

| Model | Material | Wheel Size | Weight Limit | Product Weight | Age Suitability | Compliance |

|---|---|---|---|---|---|---|

| WoodPro SmartTrike 300 | Birch plywood / non-toxic paint | 8" | 25 kg | 2.5 kg | 1.5–4 | ISO 8124, ASTM F963 |

| AluGrow Trike Pro | Aluminium alloy, EVA wheels | 9" | 35 kg | 3.2 kg | 2–5 | EN71, SGS |

| Trickey Deluxe 1 | Beech wood, Steel axles | 7" | 20 kg | 2.4 kg | 1–3 | ISO 9001 |

| ClassicRide Kids 12 Swin Tricycle | Steel, wooden accents | 12" | 50 kg | 5.5 kg | 4–8 | ANSI, CPSC |

3. Premium Product Highlight:

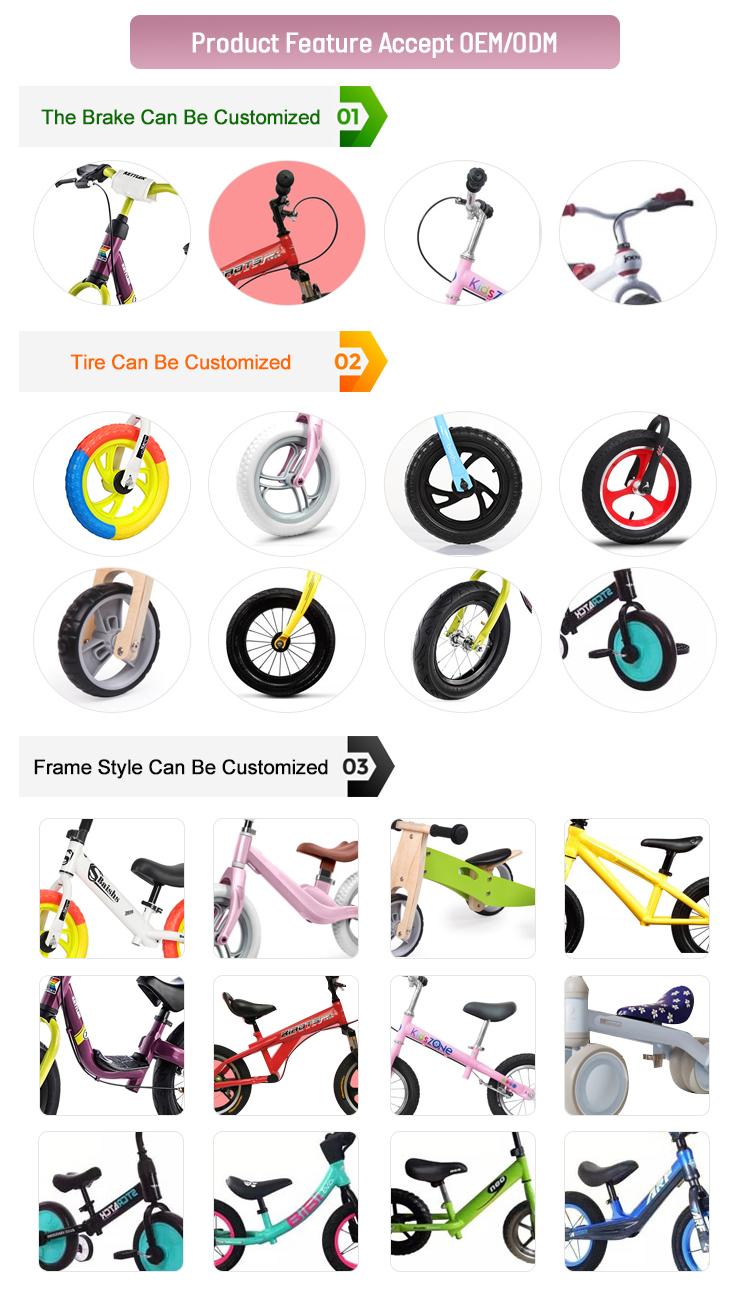

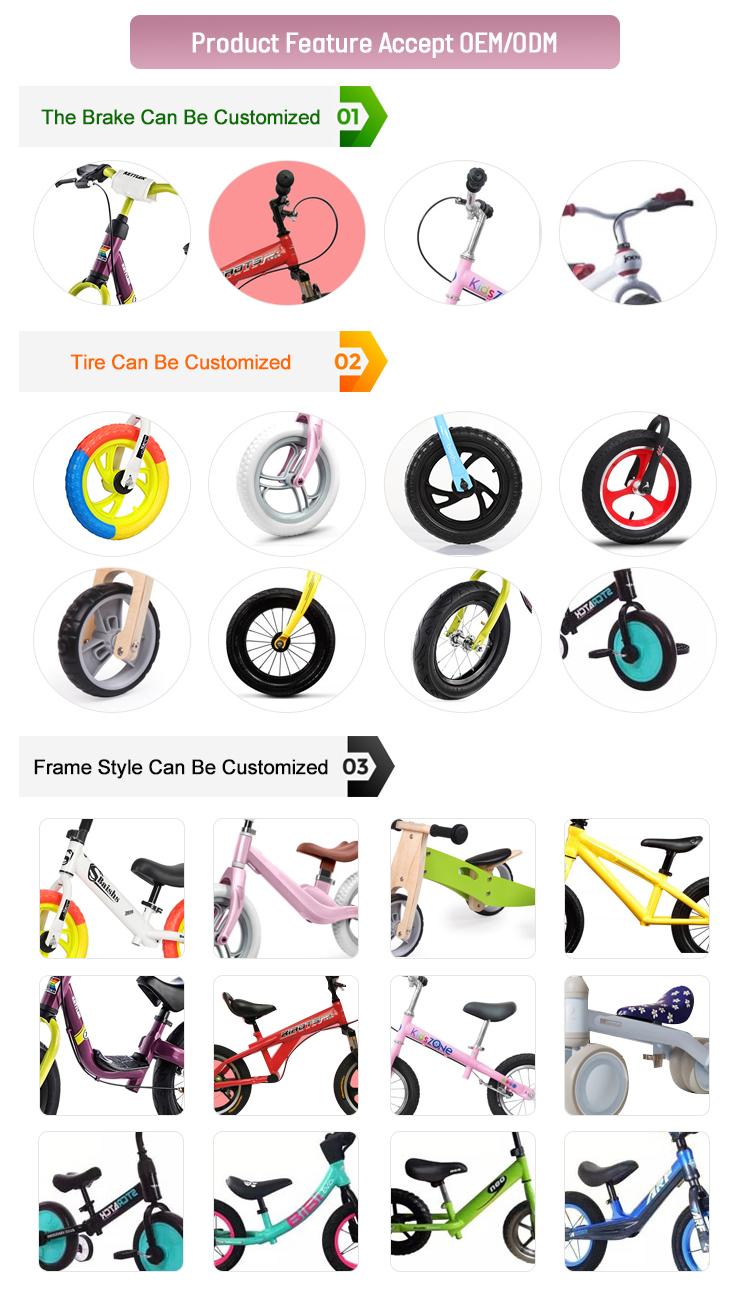

Manufacturer Wholesale ODM Aluminium Alloy Children 20 Inch Balance Bike

- Frame Material: Premium aluminium alloy (Grade 6061), ultra-light and robust.

- Wheel Size: 20 inches — ideal for kids tricycle 3+ years & up to early teens.

- Bearing System: Enclosed, maintenance-free with low friction, ≥50,000 cycles (lab tested).

- Surface: Hard anodizing for corrosion resistance (standard per ISO 9227 neutral salt spray test).

- Customization: Available for OEM/ODM with private branding.

Technical Specification Snapshot

| Parameter | Wholesale ODM Balance Bike | Standard Wooden Tricycle |

|---|---|---|

| Frame Material | Aluminium Alloy 6061 | Birch/Maple Plywood |

| Wheel Diameter | 20 inch | 7–10 inch |

| Weight Limit | 60 kg | 20–35 kg |

| Product Weight | 7.6 kg | 2.4–3.2 kg |

| Surface Finish | Anodized, Color Paint | Varnish, Paint |

| Certification | ISO 8124, SGS | ASTM, EN71 |

4. Manufacturing Process Flow: wooden tricycle for kids

- Material: FSC-certified birch/beech, or aluminium alloy per GB/T 3190-2019

- CNC Machining: Tolerance up to ±0.1mm

- Painting/Varnishing: Water-based, anti-UV, EN71-3/ASTM F963 eco-standards

- Testing: Load endurance, salt spray for corrosion, >30,000 cycles rolling test

Key Advantages:

- High-precision CNC for jointing, improved structure.

- Anti-corrosion assembly; all exposed hardware anodized or galvanized.

- Final assembly under ISO 9001:2015 QMS supervision.

- Routine third-party factory audits (SGS, BV, TUV).

Visualized: Typical Tricycle Structure

5. Application Scenarios: Age, Environments & Industry Use

From private home use to playgrounds and kindergartens, high-grade wooden tricycle for kids and alloy tricycles are increasingly used in:

- Daycare centers: Emphasis on ergonomics, cleaning-friendly materials.

- Amusement parks & rented rides: Models with enhanced impact resistance, surface custom branding.

- Pediatric clinics & therapies: Gentle rolling resistance, non-allergenic materials.

- Commercial promotion: Kids tricycle manufacturers providing logo branding for events.

| Scenario | Feature Set | Example Model |

|---|---|---|

| Outdoor Playground | UV-resistant, anti-rust hardware, wide wheels | ClassicRide 12 Swin |

| Home Indoor | Silent EVA tires, compact frame, non-marking finishes | Trickey Deluxe 1 |

| Group Rental | Easy disassembly, reinforced handle frames | AluGrow Trike Pro |

6. Industry Data Visualization

According to industry research (Statista: Bicycles/Tricycles Market), alloy tricycles slightly lead the premium market segment, but wooden tricycles remain strong, chosen for Montessori/eco-education markets.

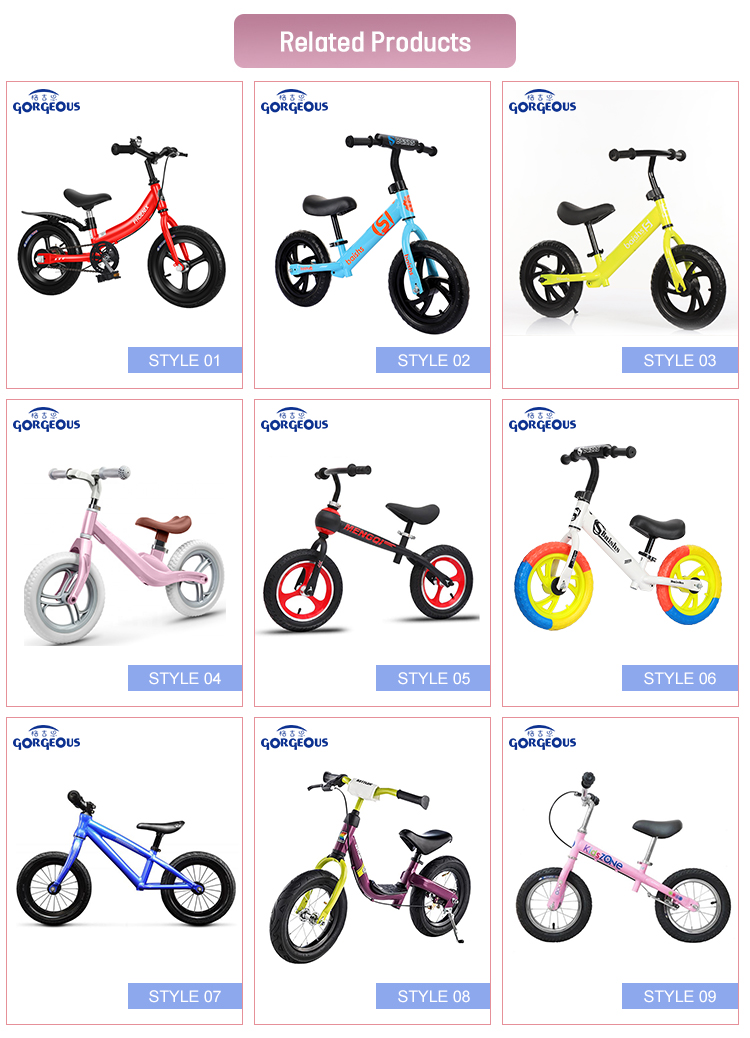

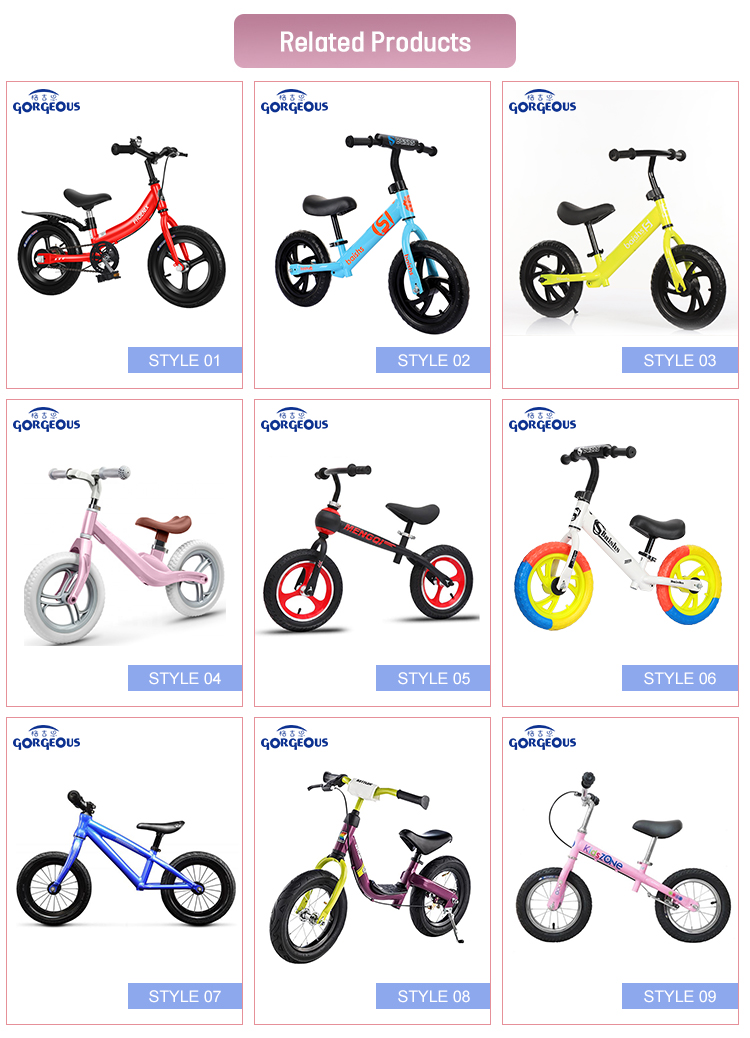

7. Manufacturer Comparison: Top kids tricycle manufacturers & kids tricycle factories

| Manufacturer | Core Material | Annual Output | ISO Certification | Lead Time | Customization |

|---|---|---|---|---|---|

| GorgeousBike | Aluminium Alloy, FSC Wood | 480,000 units | ISO 9001, ISO 8124 | 15-30 days | OEM/ODM |

| Firefly Toys | Beech, ABS, Steel | 220,000 units | EN71 | 30-45 days | OEM |

| Sunny Trikes | Plywood, Alloy | 150,000 units | ISO 9001 | 25 days | ODM |

GorgeousBike leads as one of the few kids tricycle manufacturers offering integrated production (wood/alloy), full QA traceability, and rapid custom branding (bulk-ready for B2B, e-commerce).

8. Customization Solutions

- Frame branding (logo burning, painting)

- Colorways (matched from Pantone database)

- Aluminium, steel, wood or hybrid composites

- Custom packaging (retail-ready, drop shipping)

- Child-specific ergonomics: adjustable seats, handlebars

9. Case Studies: kids tricycle bike ride Solutions & Customer Feedback

- Supplied 340+ wooden tricycle for kids with quick-swap handlebar design

- Durability: Less than 2% parts defect reported in 2 years

- Compliance: Random on-site CPSC/SGS/ASTM audits passed

- 30 x Alloy tricycles supplied (ODM spec: 20” wheels)

- Impact test completed (>7,500 cycles, 100kg overload, ISO 8098)

- Customer Feedback: “Reliability and low maintenance unmatched for commercial use.”

- Recommended kids tricycle 3+ years model with soft touch handles, hypoallergenic paint

- Reported significant engagement improvement in therapy sessions

10. Professional FAQs: wooden tricycle for kids Industry FAQ

A1: Mainly FSC-certified birch, beech, and maple, chosen for structural strength, low emission, and suitability for CNC shaping.

A2: Key standards include ISO 8124, EN71, ASTM F963, and ANSI Z315.1.

A3: Most wooden tricycles support 20–35 kg; aluminium alloy models can reach up to 60 kg (certified tests).

A4: With routine inspection, wooden tricycles last 3–5 years (outdoor), up to 8 years indoors. Alloy models may exceed 10 years due to superior corrosion/UV resistance.

A5: All products ship with ISO/ANSI-compliant manuals. Most require only 6 screws and standard hex tools (included).

A6: Yes – GorgeousBike and leading kids tricycle factories offer full customization (logo, color, packaging, even frame geometry).

A7: Typical lead time: 15–30 days. 1–3 year warranty (depending on model, component). After-sales support: onsite or remote. Damage on arrival (DOA) replacement guaranteed.

11. Delivery & After-Sales Support

- Standard Delivery: 15–30 days (ex-works)

- Sample Lead Time: 7–10 days

- Bulk warranty: 12–36 months (structure, wheels, hardware)

- 24/7 client support: multilingual, video call optional

- Video installation guides & step-by-step PDF manuals

12. Why Choose Certified wooden tricycle for kids & Manufacturer ODM?

- Complies with ISO 8124 & EN 71 – highest international savey standards

- Custom-fit for tricycle bikes for kids in educational, commercial, and residential sectors

- Verified by global audits (SGS/BV) and used by top education chains worldwide

- Trusted by distributors for durability, low return rates (<1.65%)

13. References & Industry Links

- Global Bicycle and Tricycle Market Data: Statista

- ISO Standards Queries: ISO 8124-1 Children's Products

- Industry Forums: BikeForums: Wooden Tricycles for Urban Kids

- Scholarly: Toys & Play: Wooden Ride-on Tricycles in Childcare – A Safety Review

- Certification Guide: SGS: Safe Kids Toys

-

Top Wooden Tricycle for Kids | Durable Eco-Friendly

NewsAug.05,2025

-

Eco-Friendly Wooden Tricycle for Kids - Safe & Durable Ride

NewsAug.04,2025

-

Premium Wooden Tricycle for Kids – Eco-Safe Ride

NewsAug.03,2025

-

Wooden Kids Tricycle - Eco-Friendly & Safe Ride for Toddlers

NewsAug.02,2025

-

Premium Wooden Tricycle for Kids | Safe & Eco Play

NewsAug.01,2025

-

Wooden Tricycle for Kids | Safe, Eco-Friendly Ride

NewsJul.31,2025