Sep . 22, 2025 11:45 Back to list

Wholesale Kids Tricycles | Vintage, 2-Seat & Older Kids Models

Navigating the B2B Market: Insights into Wholesale Kids Tricycles

The market for children's recreational products is dynamic and constantly evolving, with a persistent demand for durable, safe, and engaging options. Among these, the wholesale kids tricycle segment stands out as a foundational pillar for retailers, distributors, and educational institutions. This comprehensive guide delves into the intricate aspects of procuring high-quality tricycles for a B2B audience, covering everything from manufacturing excellence and technical specifications to market trends, vendor selection, and long-term support. Our focus is on providing actionable insights for decision-makers seeking to optimize their product offerings and ensure consumer satisfaction.

Current Industry Trends in Kids Tricycle Manufacturing & Distribution

The global market for children's outdoor play equipment, including tricycles, is experiencing robust growth driven by increasing parental awareness of child development and the importance of physical activity. Key trends shaping the wholesale kids tricycle sector include:

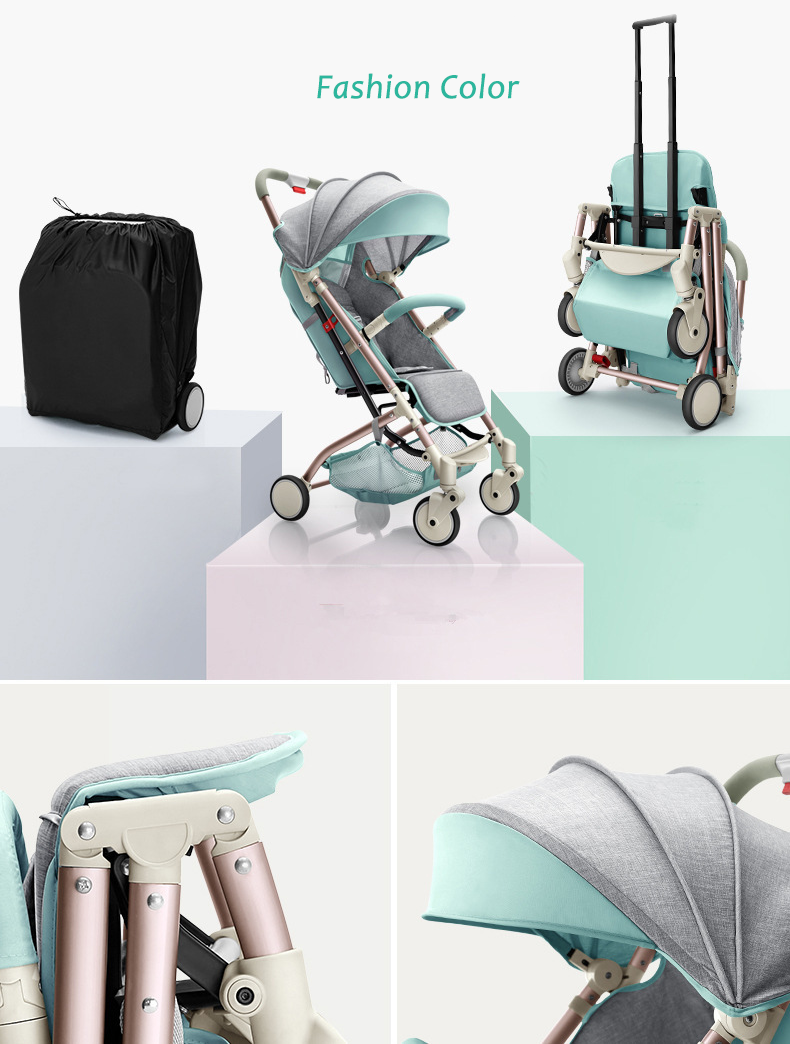

- Multi-functionality and Adaptability: Demand for 3-in-1 or 4-in-1 tricycles that grow with the child, transforming from a push-along stroller to a full-fledged tricycle. This includes models catering to tricycle for older kids and even tricycle kids 10 yrs old with robust designs.

- Sustainable and Non-Toxic Materials: A growing preference for eco-friendly plastics, recycled metals, and phthalate-free components, ensuring both environmental responsibility and child safety.

- Ergonomics and Safety Enhancements: Advanced ergonomic designs for comfortable seating, adjustable handlebars, secure harness systems, and improved braking mechanisms are paramount. Compliance with international safety standards like EN71 (Europe) and ASTM F963 (USA) is a non-negotiable aspect.

- Design Aesthetics: A surge in contemporary designs, often incorporating vibrant colors and character themes like the popular tricycle for kids minnie, alongside a niche market for styles inspired by vintage kids tricycle aesthetics, offering unique appeal.

- Digital Distribution Channels: The increasing shift towards tricycle for kids online wholesale platforms, allowing for broader market reach and efficient logistics for distributors in regions like the tricycle for kids uk market.

Technical Specifications and Advanced Materials for Quality Tricycles

Understanding the technical specifications and material science behind a wholesale kids tricycle is crucial for B2B buyers. The longevity, safety, and performance of the product are directly tied to these factors.

Frame Construction and Materials:

- High-Carbon Steel: Offers exceptional strength-to-weight ratio and durability, often treated with powder coating for superior corrosion resistance and aesthetic appeal. This is typical for robust models, including those designed for older children.

- Aluminum Alloy: Lighter than steel, making tricycles easier to maneuver for children and parents. Aluminum frames are naturally resistant to rust and can be anodized for color and additional protection.

- Reinforced Plastic (e.g., HDPE, PP): Used for lighter, often foldable models, especially for younger children. These plastics are chosen for their impact resistance, non-toxicity, and vibrant color retention.

Wheel and Tire Systems:

- EVA Tires (Ethylene-vinyl acetate): Puncture-proof, lightweight, and maintenance-free. Ideal for indoor or smooth outdoor surfaces. Common in entry-level tricycles.

- Pneumatic Rubber Tires: Provide superior shock absorption and grip, suitable for varied terrains. They offer a smoother ride but require occasional inflation and are more puncture-prone. Often found on premium models or tricycle for older kids.

- Solid Rubber/PU Wheels: A balance between EVA and pneumatic, offering good durability and grip without the need for inflation.

Safety and Ergonomic Features:

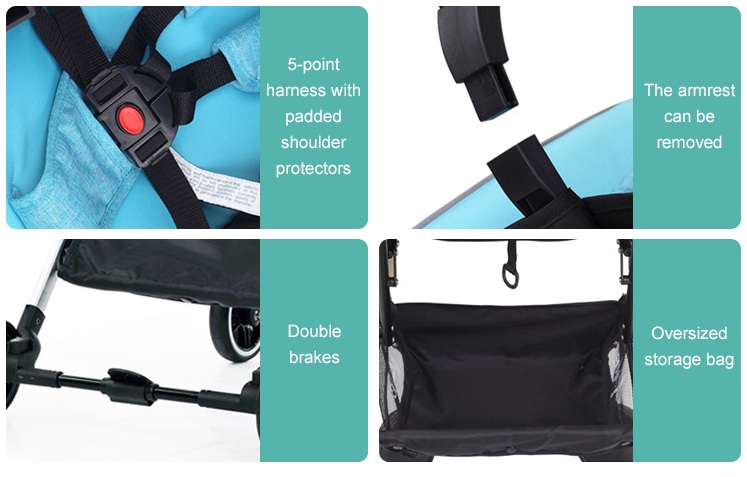

- Adjustable Seating and Handlebars: Accommodates growing children, extending the product's useful life.

- Safety Harnesses (3-point or 5-point): Essential for younger riders, ensuring they remain securely seated.

- Parent Push Handle: Detachable and adjustable, allowing parents to guide the tricycle, particularly useful for younger children or two seat tricycle kids models.

- Braking Systems: Rear-wheel foot brakes or handbrakes for enhanced control and safety.

Typical Product Specification Table: Modern Kids Tricycle

| Parameter | Specification |

|---|---|

| Frame Material | High-Carbon Steel (powder-coated) or Aluminum Alloy |

| Wheel Type | EVA (Puncture-Proof) or Pneumatic Rubber |

| Recommended Age | 18 months to 5 years (up to 25 kg/55 lbs) |

| Weight Capacity | Up to 25 kg (55 lbs) for rider, 5 kg (11 lbs) for storage basket |

| Product Dimensions (L x W x H) | 90 cm x 50 cm x 100 cm (approx. assembled) |

| Product Weight | 5-8 kg (depending on model and materials) |

| Safety Standards | CE, EN71-1-2-3, ASTM F963, ISO 8124 |

| Features | Adjustable Parent Handle, Foldable Design, 3-point Safety Harness, Storage Basket, Detachable Canopy |

| Warranty | 1-2 years standard manufacturing warranty |

The Manufacturing Process of a Quality Wholesale Kids Tricycle

The production of a high-quality wholesale kids tricycle involves a series of meticulously controlled stages, from raw material selection to final assembly and rigorous testing. Adherence to strict manufacturing protocols ensures the product's integrity, safety, and durability, thereby minimizing recalls and maximizing customer satisfaction.

Manufacturing Process Flow: From Concept to Consumer

-

1. Material Sourcing & Preparation: We begin with selecting certified, high-grade materials. This includes robust steel or aluminum alloys for frames, ensuring structural integrity and corrosion resistance, and non-toxic, impact-resistant plastics (e.g., PP, HDPE, ABS) for seats, wheels, and accessories. All materials undergo initial quality checks for compliance with RoHS and REACH standards, ensuring they are free from harmful substances.

-

2. Frame Production:

- Cutting & Bending: Precision CNC machining is utilized to cut and bend metal tubing to exact specifications, ensuring consistent geometry for all components. This minimizes human error and guarantees part interchangeability.

- Welding: Robotic MIG (Metal Inert Gas) or TIG (Tungsten Inert Gas) welding is employed for joining frame components. This automated process ensures uniform, high-strength welds that are critical for the overall structural integrity and service life of the tricycle kids antique durable frame designs.

- Surface Treatment: Frames undergo a multi-stage cleaning process before receiving an electrostatic powder coating. This provides a durable, chip-resistant finish that significantly enhances corrosion resistance, extending the product's lifespan even in varied environmental conditions.

-

3. Component Manufacturing: This stage involves the production of various sub-components.

- Wheel Assembly: Injection molding creates plastic hubs, while tires (EVA or rubber) are molded and assembled. Precision bearings are integrated for smooth rotation.

- Seat Molding: Ergonomically designed seats are produced via injection molding using child-safe, durable plastics. Padding and covers are added in compliance with fire safety standards.

- Accessory Production: Handlebars, pedals (often through casting or injection molding), and storage baskets are manufactured and pre-assembled.

-

4. Assembly Line: Components converge on a semi-automated assembly line. Skilled technicians perform precise assembly, integrating frame, wheels, steering mechanisms, seats, and safety features. Each station includes in-process quality checks to identify and rectify any deviations immediately.

-

5. Quality Control & Testing: This critical stage ensures every wholesale kids tricycle meets the highest international safety and performance standards.

- Mechanical Safety Testing: Includes drop tests, impact resistance tests, stability tests (to prevent tipping), and load-bearing capacity tests.

- Chemical Safety Testing: Materials are tested for lead, phthalates, and other harmful chemicals as per EN71-3, ASTM F963, and CPSIA requirements.

- Functionality & Durability Testing: Steering, braking, wheel rotation, and adjustability features are all tested. Lifecycle testing simulates years of typical use to ensure long-term performance and service life, often exceeding 5 years.

- Compliance Certification: Products are regularly audited and certified by independent bodies against ISO 9001 for quality management systems, EN71, ASTM F963, and ISO 8124 for toy safety.

-

6. Packaging & Distribution: Tricycles are carefully packaged using robust, often eco-friendly, materials to prevent damage during transit. Detailed assembly instructions and safety warnings are included. Efficient logistics networks ensure timely and cost-effective delivery to target industries, which typically include mass-market retailers, specialized children's stores, online distributors (e.g., for tricycle for kids online), and educational institutions (daycare centers, preschools).

Advantages in Typical Application Scenarios:

Our manufacturing approach yields distinct advantages for B2B clients:

- Energy Saving: Optimized production lines and material utilization reduce waste and energy consumption, contributing to a more sustainable supply chain.

- Corrosion Resistance: High-quality powder coatings and material choices ensure products withstand environmental factors, enhancing their lifespan and reducing maintenance needs for end-users. This is especially vital for products like vintage zenith kids tricycle inspired models that are expected to last for generations.

- Enhanced Safety & Durability: Rigorous testing and adherence to international standards mean fewer product failures, greater child safety, and a stronger brand reputation for our partners.

Application Scenarios and Target Markets

The versatility and broad appeal of the wholesale kids tricycle make it a staple product across numerous B2B channels. Understanding these application scenarios helps refine product selection and marketing strategies.

- Retail Chains (Mass Market & Specialty): Large retailers and boutique children's stores consistently stock tricycles due to high consumer demand. Product ranges can vary from basic models to premium, feature-rich options or those with specific branding like tricycle for kids minnie.

- Online E-commerce Platforms: With the surge in online shopping, distributors focused on tricycle for kids online benefit from comprehensive product data, high-resolution imagery, and efficient direct-to-consumer shipping capabilities. This market particularly thrives on strong product descriptions and customer reviews.

- Educational Institutions: Daycare centers, preschools, and kindergartens require extremely durable and safety-certified tricycles that can withstand constant use by multiple children. Features such as robust construction and easy-to-clean surfaces are highly valued here. Models like two seat tricycle kids are often sought for cooperative play.

- Rental Services & Tourism: In parks, resorts, and tourist areas, tricycle rental services offer recreational opportunities. These require heavy-duty models with minimal maintenance needs and high wear resistance, often for diverse age groups, including tricycle for older kids.

- Export Markets: Companies targeting international markets, such as the tricycle for kids uk market, must ensure their products comply with specific regional safety standards and cultural preferences, requiring adaptable product lines and logistics.

Technical Advantages of Modern Wholesale Kids Tricycles

Modern manufacturing and design principles imbue today's wholesale kids tricycle offerings with significant technical advantages that elevate them beyond traditional models.

- Superior Durability and Longevity: Utilization of advanced materials like robust steel alloys with multi-layer powder coating, or lightweight aerospace-grade aluminum, ensures frames withstand rigorous use and environmental exposure. This focus on enduring construction echoes the quality seen in a vintage zenith kids tricycle, known for its lasting appeal.

- Enhanced Safety Systems: Beyond basic harnesses, modern tricycles incorporate anti-tip designs, responsive braking systems, non-slip pedals, and fully enclosed chain guards (where applicable), drastically reducing accident risks. Materials are rigorously tested to be free from lead, phthalates, and other harmful chemicals.

- Ergonomic Design for Child Development: Adjustable seats, handlebars, and footrests cater to a child's growth, promoting proper posture and comfortable riding over extended periods. This thoughtful design supports motor skill development and ensures a comfortable experience even for a tricycle kids 10 yrs old.

- Innovative Features: Many models now feature one-hand folding mechanisms for easy transport and storage, parental steering systems, integrated storage compartments, and even interactive elements that enhance engagement. The adaptability of models that transition from a stroller to a pedal tricycle underscores this innovation.

- Compliance with Global Safety Standards: Manufacturers committed to quality ensure their tricycles meet or exceed international safety certifications such as EN71 (European Toy Safety Directive) and ASTM F963 (U.S. Standard Consumer Safety Specification for Toy Safety). This is a critical factor for B2B partners, especially for tricycle for kids uk and other export markets.

Vendor Comparison: Choosing the Right Wholesale Partner

Selecting the right supplier for wholesale kids tricycle products is a strategic decision that impacts product quality, supply chain reliability, and ultimately, profitability. B2B buyers must evaluate vendors on multiple criteria beyond just price.

Key Evaluation Factors:

- Quality Certifications and Compliance: Verify certifications like ISO 9001 (Quality Management), EN71, ASTM F963, and CE marks. These demonstrate a commitment to manufacturing excellence and product safety.

- Manufacturing Capacity and Scalability: Assess a vendor's ability to handle order volumes, especially during peak seasons, and their flexibility to scale production for growing demand.

- Customization Options: For brands looking to differentiate, the ability to customize colors, branding, specific features (e.g., two seat tricycle kids configurations), or packaging is crucial.

- Pricing Structure and Payment Terms: Evaluate competitive pricing, volume discounts, and favorable payment terms that align with your business's financial model.

- Lead Times and Logistics: Understand typical lead times for production and shipping, as well as the vendor's logistical capabilities for domestic and international deliveries (e.g., to the tricycle for kids uk market).

- After-Sales Support and Warranty: A robust warranty policy, availability of spare parts, and responsive customer service are indicators of a reliable long-term partner.

- Reputation and Experience: Look for vendors with a proven track record, positive industry reviews, and long-standing relationships with other B2B clients.

Wholesale Kids Tricycle Vendor Comparison Matrix (Illustrative)

| Feature/Vendor | Vendor A | Vendor B | Vendor C |

|---|---|---|---|

| Certifications (EN71, ASTM) | Yes | Yes | Partial |

| Frame Material Options | Steel, Al-Alloy | Steel, Plastic | Steel |

| Customization Level | High (Color, Logo, Features) | Medium (Color, Logo) | Low (Logo only) |

| Minimum Order Quantity (MOQ) | 500 units | 200 units | 1000 units |

| Average Lead Time (Production) | 30-45 days | 45-60 days | 60+ days |

| Warranty Period | 2 years | 1 year | 6 months |

| Customer Support Responsiveness | Excellent | Good | Fair |

Customized Solutions for Wholesale Clients

In the competitive B2B landscape, offering tailored solutions can significantly enhance market positioning and brand loyalty. For wholesale kids tricycle procurement, customization extends beyond mere branding.

- Brand Integration: This is fundamental. Custom colors, logo placements on the frame, seat, or canopy, and branded accessories (e.g., bell, basket) allow distributors to create a distinct product line that resonates with their target audience.

- Feature Modification: Clients can request specific alterations to existing models. This might include different wheel types (e.g., pneumatic for rough terrains, EVA for indoors), alternative braking systems, enhanced storage options, or specialized safety features. For instance, a two seat tricycle kids model might require specific stability enhancements for heavier loads.

- Material Upgrades/Downgrades: Depending on budget and target market, a client might request a switch from steel to aluminum for a lighter product, or a specific type of non-toxic plastic for specific components, ensuring compliance with local regulations.

- Packaging Design: Custom packaging not only reinforces branding but also addresses logistical needs. This can involve compact designs for tricycle for kids online sales, or bulk packaging for institutional delivery, with multilingual instructions as required.

- Age-Specific Adaptations: Customization can focus on specific age groups, such as designing a more robust and stable tricycle for older kids or a simplified, lightweight version for toddlers. This also encompasses adapting designs for themes like tricycle for kids minnie which appeal to specific demographics.

Our engineering and design teams work closely with B2B partners to translate market needs into tangible product specifications, ensuring that custom solutions are not only innovative but also meet stringent safety and quality standards.

Application Case Studies (Experience & Authoritativeness)

Real-world applications demonstrate the tangible benefits of partnering with a quality wholesale kids tricycle manufacturer. These case studies highlight successful implementations across diverse B2B environments.

Case Study 1: Major European Retail Chain Integration

A prominent European retail chain sought to refresh its children's ride-on toy category. They partnered with our firm to supply a new line of wholesale kids tricycle models. The key requirements included adherence to stringent EN71 standards, a diverse product range appealing to different age groups (including tricycle kids 10 yrs old and toddler models), and consistent supply chain reliability. We delivered a collection featuring robust steel frames, ergonomic designs, and attractive colorways. The comprehensive safety documentation and consistent product quality led to a 20% increase in tricycle sales within the first year and a significant reduction in customer complaints. The chain praised our ability to adapt packaging for efficient in-store display and online distribution for the tricycle for kids uk market.

"Our partnership has revitalized our outdoor play category, with customer feedback consistently highlighting the exceptional durability and safety of the tricycles. The reliable supply chain has been instrumental in meeting seasonal demands." - Purchasing Director, European Retail Group.

Case Study 2: National Daycare & Educational Supplier

A leading supplier to daycare centers and preschools across a major country required a fleet of highly durable and low-maintenance tricycles. Their priority was unparalleled safety and longevity under constant, intensive use. We provided a customized line of wholesale kids tricycle models with reinforced aluminum frames, puncture-proof EVA tires, and enhanced stability features. The tricycles met ISO 8124 and local educational safety guidelines. Our products' robustness led to a documented 40% reduction in replacement costs for the supplier over a three-year period, alongside overwhelmingly positive feedback from educators regarding durability and child engagement. Specialized two seat tricycle kids models were particularly popular for fostering social play.

"The longevity of these tricycles is outstanding. They stand up to daily use by dozens of children, requiring minimal maintenance. This has been a significant cost-saver for our partners." - Operations Manager, Educational Supplier.

Ensuring Trustworthiness: FAQs, Lead Times, Warranty, and Support

Building trust is paramount in B2B relationships. We are committed to transparency and exceptional support for our wholesale kids tricycle partners.

Frequently Asked Questions (FAQs) for Wholesale Clients:

Q: What safety standards do your tricycles meet?

A: All our tricycles are designed and tested to meet or exceed international safety standards, including EN71 (European Union), ASTM F963 (United States), and ISO 8124 (International). We hold CE certifications and conduct regular third-party audits.

Q: What materials are primarily used in your tricycles?

A: We use high-grade, durable materials such as powder-coated high-carbon steel or aluminum alloy for frames, non-toxic and impact-resistant PP/HDPE plastics for seats and wheels, and EVA or pneumatic rubber for tires. All materials are tested for harmful chemicals like phthalates and lead.

Q: Can we customize designs, colors, or add our branding?

A: Yes, we offer extensive customization options for wholesale kids tricycle orders. This includes custom colors, logo integration (pad printing, decals), feature modifications (e.g., specific wheel types, storage solutions), and custom packaging design to match your brand requirements. Minimum order quantities apply for customization.

Q: What is the typical lead time for a bulk order?

A: Standard lead times for production typically range from 30 to 45 days after order confirmation and deposit, depending on the volume and level of customization. Shipping times vary based on destination and chosen freight method. We provide detailed timelines upon order placement.

Q: What is your warranty policy for wholesale products?

A: We offer a standard 1-2 year warranty against manufacturing defects for all our wholesale kids tricycle products. Specific terms and conditions are outlined in our wholesale agreement. This covers material and workmanship flaws under normal use. We also ensure availability of spare parts.

Lead Time & Fulfillment Details:

Our streamlined production process and robust supply chain enable efficient order fulfillment. We typically require a 30% down payment to initiate production, with the balance due upon shipment. Lead times are clearly communicated at the time of quotation and order confirmation. We work with established logistics partners to offer flexible shipping options (FOB, CIF, DDP) globally, ensuring timely delivery to your warehouse or distribution center, whether you're ordering tricycle for kids uk or for other international markets.

Warranty Commitments:

We stand by the quality of our wholesale kids tricycle products with a comprehensive warranty program. This typically covers manufacturing defects for a period of 12 to 24 months from the date of purchase, ensuring peace of mind for our B2B partners and their end-customers. Our warranty policy is designed to be clear, fair, and easily accessible, facilitating efficient resolution of any potential product issues.

Dedicated Customer Support:

Our commitment to our partners extends beyond product delivery. Each wholesale client is assigned a dedicated account manager who serves as a single point of contact for all inquiries, from order tracking to technical support. We provide comprehensive after-sales assistance, including access to spare parts, assembly guides, and marketing materials. Our goal is to forge long-term, mutually beneficial relationships built on trust, reliability, and proactive support.

Conclusion

The strategic procurement of wholesale kids tricycle products is a cornerstone for businesses operating in the juvenile products market. By prioritizing manufacturers who adhere to rigorous technical specifications, embrace advanced manufacturing processes, and demonstrate a steadfast commitment to safety, durability, and customer support, B2B partners can ensure they offer products that not only delight consumers but also build long-term brand equity. The evolving landscape demands innovative, adaptable, and trustworthy solutions, and by focusing on these core principles, businesses can successfully navigate the market and achieve sustainable growth.

From the precision of CNC machining in frame construction to the meticulous testing against global safety standards like EN71, every aspect of a quality tricycle's lifecycle is engineered for excellence. Whether meeting the demand for modern, multi-functional designs or catering to a nostalgic appreciation for a tricycle kids antique aesthetic, the underlying commitment to quality remains constant. Partnering with the right manufacturer offers not just products, but a pathway to market leadership and consumer trust.

References

- European Committee for Standardization. EN 71 Safety of toys - Part 1: Mechanical and physical properties. Available from: EN-Standard.eu

- ASTM International. ASTM F963 - Standard Consumer Safety Specification for Toy Safety. Available from: ASTM.org

- International Organization for Standardization. ISO 9001: Quality management systems. Available from: ISO.org

- U.S. Consumer Product Safety Commission (CPSC). Children's Product Safety Guidance. Available from: CPSC.gov

-

The Essential Guide to 16 Inch Child's Bikes – Safety, Specs & Trends

NewsNov.24,2025

-

Kids Road Bike 24 – Lightweight, Safe, and Perfect for Young Cyclists

NewsNov.23,2025

-

Discover Safe and Fun Children's Bikes 14 Inch | Durable Kids' Bikes Reviewed

NewsNov.22,2025

-

Discover the Perfect Little Girl 16 Inch Bike – Safety, Style & Performance

NewsNov.22,2025

-

The Ultimate Guide to 12 Kids Bicycles – Safety, Trends & Top Picks

NewsNov.21,2025

-

14 Inch Children’s Bikes: A Guide to Safety, Durability & Global Impact

NewsNov.20,2025