Sep . 22, 2025 13:25 Back to list

Premium Wooden Tricycle for Kids - Safe, Sturdy & Fun

Navigating the Market: Industry Trends in Children's Mobility Solutions

The global children's ride-on toy market is experiencing robust growth, driven by increasing parental awareness of child development, safety, and sustainable product choices. Within this dynamic landscape, the demand for classic yet ergonomically superior options like the wooden tricycle for kids is witnessing a significant resurgence. Parents and educators are increasingly prioritizing natural materials, durable construction, and designs that foster motor skill development without compromising on aesthetic appeal. This trend extends to related segments such as the wholesale kids tricycle market, where bulk purchasers for kindergartens, daycare centers, and specialized retail outlets seek high-quality, long-lasting products that meet stringent safety standards.

Further market analysis indicates a growing appreciation for vintage-inspired designs. Concepts like the vintage zenith kids tricycle or a vintage gold kids tricycle resonate with consumers looking for timeless pieces that offer both functionality and nostalgic charm. This emphasis on heritage and craftsmanship often aligns seamlessly with the attributes inherent in wooden constructions. Additionally, the increasing demand for specialized products, such as a two seats kids tricycle or a two seater kids tricycle, highlights the need for versatile designs that cater to sibling play or peer interaction, enhancing social development alongside physical activity. Suppliers who can effectively combine these market demands with robust manufacturing and supply chain capabilities are best positioned for success.

The Art of Crafting a wooden tricycle for kids: Manufacturing Process and Quality Assurance

The production of a high-quality wooden tricycle for kids is an intricate process that combines traditional woodworking techniques with modern precision engineering. It begins with meticulous material selection, ensuring both durability and child safety.

Process Flow: From Raw Material to Finished Product

- Material Sourcing & Selection: Premium hardwoods like Baltic birch, beech, or sustainable rubberwood are chosen for their strength, stability, and fine grain. These woods are naturally non-toxic and provide excellent structural integrity. Certification for sustainable forestry (e.g., FSC) is often a prerequisite.

- Precision Cutting & Milling: State-of-the-art CNC machining centers are employed to cut and shape wooden components with exceptional accuracy. This ensures perfect fitment, smooth edges, and consistent product dimensions, critical for stability and assembly.

- Sanding & Edge Finishing: Each wooden piece undergoes multiple stages of sanding, from coarse to fine grit, to achieve a perfectly smooth, splinter-free surface. All edges are rounded or chamfered to eliminate sharp points, enhancing child safety.

- Joinery & Assembly Preparation: Components are drilled, routed, and prepared for robust joinery. This often involves dowel joints, mortise and tenon, or secure mechanical fasteners designed to withstand vigorous play.

- Non-Toxic Finishing: A crucial step involves applying child-safe, non-toxic, lead-free paints, stains, or clear lacquers that comply with international safety standards like EN 71-3 (migration of certain elements) and ASTM F963. This finish protects the wood and adds aesthetic appeal.

- Component Integration: Wheels (often rubber-lined for floor protection and quiet operation), axles, and steering mechanisms are integrated. Bearings, if used, are typically sealed for low maintenance and smooth operation.

- Final Assembly & Quality Control: Trained technicians assemble the tricycles, ensuring all parts fit correctly and function as intended. Each unit undergoes rigorous quality control checks, including structural integrity, finish adhesion, and compliance with all design specifications.

- Packaging: Products are carefully packaged to prevent damage during transit, often using eco-friendly materials.

Target industries for these robust products include early childhood education facilities, specialized toy retailers, interior design firms for children's spaces, and hospitality groups looking for durable, aesthetically pleasing children's amenities. The service life of a well-constructed wooden tricycle for kids can exceed 5-10 years, making it a sustainable and cost-effective investment.

Technical Specifications and Ergonomic Design Principles

A superior wooden tricycle for kids is not merely a toy; it is a carefully engineered mobility device designed to support a child's physical development. Understanding the technical parameters is crucial for B2B buyers evaluating product suitability and long-term value.

Standard Product Specifications for a Premium Wooden Tricycle

| Parameter | Specification | Notes/Benefit |

|---|---|---|

| Primary Material | FSC-certified Baltic Birch Plywood or Solid Beechwood | Exceptional strength-to-weight ratio, splinter-resistant, sustainable sourcing. |

| Finish | Water-based, non-toxic, lead-free lacquer/paint | EN 71-3 & ASTM F963 compliant, child-safe, durable, easy to clean. |

| Dimensions (L x W x H) | Approx. 55-65 cm x 30-40 cm x 38-45 cm | Ergonomically designed for various age groups (e.g., 12 months to 3 years). |

| Seat Height | Adjustable, typically 22-28 cm | Accommodates growth, promotes proper leg extension for balance and propulsion. |

| Wheel Material | Solid Rubber (non-marking) on wooden hubs | Quiet operation, superior grip on various surfaces, floor protection, long-lasting. |

| Weight Capacity | Up to 25 kg (55 lbs) | Robust construction suitable for active toddlers. |

| Product Weight | Approx. 3-4 kg (6.6-8.8 lbs) | Light enough for toddlers to maneuver, heavy enough for stability. |

| Steering Mechanism | Limited turning radius (e.g., 30-degree arc) | Prevents sharp turns and tipping, enhancing safety for young riders. |

| Safety Certifications | EN 71 (Europe), ASTM F963 (USA), SOR/2011-17 (Canada) | Compliance with global toy safety standards for B2B export readiness. |

Ergonomic design considerations include a low center of gravity for stability, appropriately sized handlebars for small hands, and a saddle contoured for comfort and support. These elements collectively contribute to a safe and enjoyable riding experience, crucial for both commercial operators and end-consumers.

Application Scenarios and Industry Impact

The versatility and durability of a high-quality wooden tricycle for kids make it an ideal choice across a spectrum of commercial and educational environments. Its robust construction and adherence to safety standards ensure suitability for high-usage settings where product longevity and child welfare are paramount.

Typical Application Fields:

- Early Childhood Education Centers: Kindergartens, preschools, and daycare facilities utilize these tricycles for gross motor skill development, coordination, and social interaction during playtime. The natural aesthetic often complements Montessori and Waldorf educational philosophies.

- Specialized Toy Retailers: High-end toy stores and educational retailers seek out premium wooden tricycles due to consumer demand for sustainable, durable, and aesthetically pleasing products. Options like a vintage kids tricycle or a vintage gold kids tricycle are particularly popular for their unique market appeal.

- Family-Friendly Hospitality & Leisure: Resorts, hotels with kids' clubs, and family entertainment centers integrate durable tricycles into their amenities to enhance guest experience. The robust nature of wood withstands heavy use in commercial environments.

- Therapeutic Settings: Occupational therapy and physical therapy centers for children often use tricycles as a tool for developing balance, coordination, and strength in a fun and engaging manner.

- Residential Developers & Interior Designers: High-end residential projects often include dedicated children's play areas, where the aesthetic and quality of wooden tricycles align with premium finishes and materials.

The impact extends beyond mere product provision; it contributes to a brand's commitment to sustainability and child-centric development. Opting for a wooden tricycle for kids demonstrates a responsible approach to material sourcing and product design, resonating positively with discerning B2B clients and their end-users.

Key Technical Advantages of a wooden tricycle for kids

Beyond aesthetics, a premium wooden tricycle for kids offers distinct technical and practical advantages that make it a superior choice for institutional and commercial buyers, particularly when compared to metal or plastic alternatives.

Comparative Advantages:

- Durability & Longevity: High-grade wooden construction, especially multi-ply birch or solid beech, provides exceptional structural integrity that resists bending, cracking, and fatigue common in plastic components. This leads to a significantly longer service life, reducing replacement costs for commercial operators.

- Environmental Sustainability: Sourced from sustainably managed forests (FSC certified), wood is a renewable resource, offering a reduced carbon footprint compared to petroleum-derived plastics or energy-intensive metal production. Biodegradable at end-of-life.

- Enhanced Safety Profile: Smooth, splinter-free finishes and carefully rounded edges minimize injury risks. The inherent rigidity of wood, combined with engineered limited steering angles, provides superior stability and prevents accidental tipping, especially for younger users.

- Tactile and Sensory Experience: The natural warmth and texture of wood offer a superior sensory experience for children, supporting developmental play. Unlike cold metal or synthetic plastic, wood is pleasant to touch and hold.

- Aesthetic Value & Integration: Wooden tricycles possess a classic, timeless appeal that integrates seamlessly into diverse interior designs, from modern minimalist to traditional settings. This is particularly valuable for B2B applications in retail and hospitality.

For entities seeking sustainable, robust, and developmentally appropriate children's mobility solutions, the advantages of a well-engineered wooden tricycle are clear and compelling.

Vendor Comparison and Strategic Sourcing for wholesale kids tricycle

Selecting the right manufacturer or supplier for a wholesale kids tricycle is a critical decision for B2B buyers. A thorough vendor comparison goes beyond price, encompassing quality, certifications, customization capabilities, and after-sales support.

Key Factors in Vendor Evaluation:

- Manufacturing Expertise: Assess the vendor's experience with precision woodworking and toy manufacturing. Look for adherence to ISO 9001 quality management systems.

- Certifications and Compliance: Verify product certifications (EN 71, ASTM F963, CE marking) and material certifications (FSC for wood). This ensures legal compliance and safety for end-users.

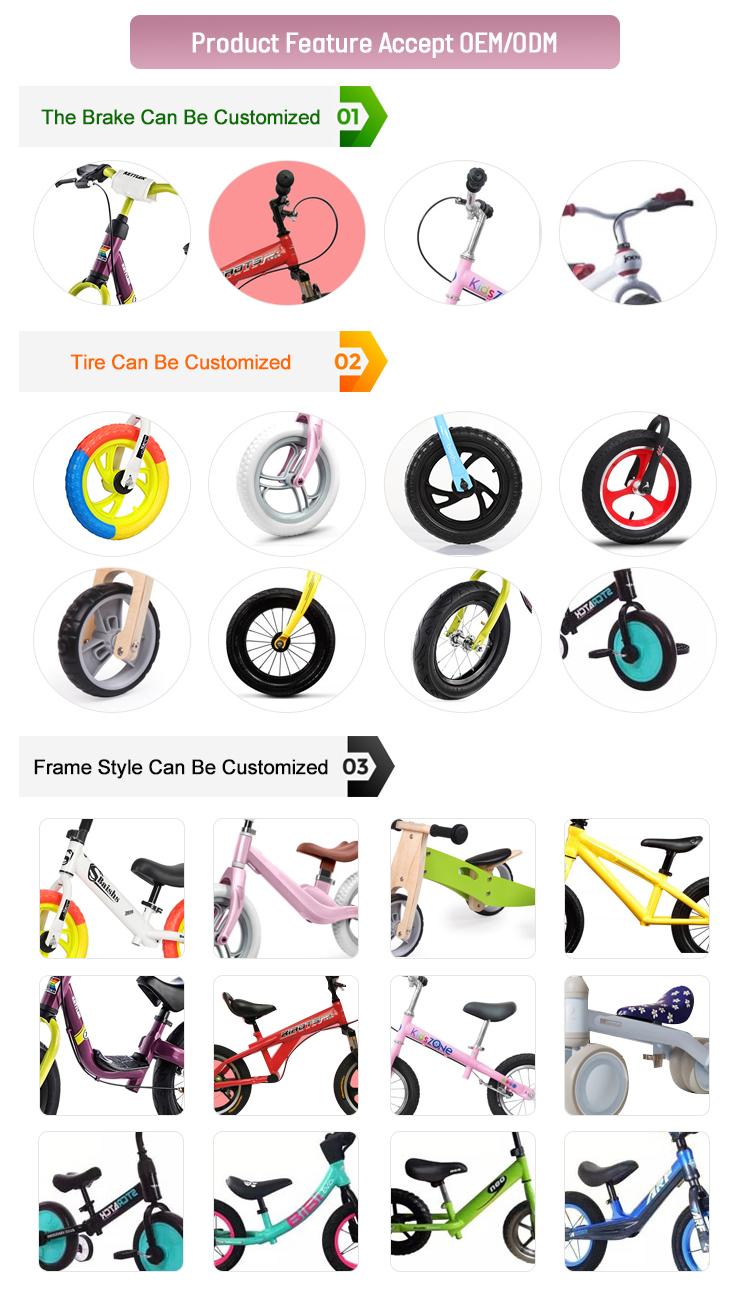

- Customization Capabilities: For specific branding or unique product lines (e.g., a specific shade for a vintage gold kids tricycle), inquire about OEM/ODM services, including custom finishes, branding, and design modifications.

- Supply Chain Reliability: Evaluate lead times, production capacity, and logistics capabilities, especially for international shipping. A robust supply chain minimizes delays and ensures timely delivery for retail seasons or educational facility openings.

- Reputation and Client Testimonials: Review customer feedback, case studies, and partner clients to gauge the vendor's track record and commitment to satisfaction.

Vendor Comparison Table (Illustrative)

| Feature | Vendor A (Specialist Wood Tricycles) | Vendor B (General Toy Manufacturer) |

|---|---|---|

| Primary Material Focus | FSC-certified Birch/Beech | Mixed (Plastic, Metal, some Wood) |

| Safety Certifications | EN 71, ASTM F963, CE, CPSIA | EN 71, CE (basic compliance) |

| Customization (OEM/ODM) | Extensive (colors, branding, design mods) | Limited (logo placement only) |

| Minimum Order Quantity (MOQ) | 500 units | 1000 units |

| Lead Time (Standard) | 30-45 days | 45-60 days |

| Warranty | 2 years structural | 1 year manufacturing defects |

Choosing a vendor with a clear focus on wooden products generally ensures deeper expertise in material handling, finish application, and safety compliance specific to wood. This specialized approach often leads to a superior wooden tricycle for kids that excels in quality and longevity.

Customized Solutions and OEM Capabilities

For B2B partners, the ability to offer customized solutions is a significant differentiator. Leading manufacturers of the wooden tricycle for kids provide comprehensive OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) services, allowing businesses to tailor products to their specific market needs or brand identity.

Tailoring Your wooden tricycle for kids:

- Design Modifications: From minor aesthetic tweaks to significant structural re-engineering, manufacturers can adapt existing designs or create entirely new models. This includes developing a two seat tricycle kids or a specific vintage zenith kids tricycle variant.

- Branding & Packaging: Incorporate your company's logo, color scheme, and specific packaging requirements to reinforce brand presence in the market. Custom labels, instruction manuals, and retail-ready packaging are standard offerings.

- Material & Finish Options: Specify preferred wood types (e.g., maple for lighter weight, oak for pronounced grain), non-toxic paint colors, or natural oil finishes to match your brand's aesthetic and sustainability goals.

- Accessory Integration: Customize features such as seating materials, handlebar grips, or even add-on accessories like small storage baskets, extending the functionality and appeal of the tricycle. This is particularly relevant for a two seater tricycle for kids, which might benefit from integrated safety belts or additional handlebars.

Engaging with manufacturers that possess strong R&D capabilities and a flexible production line ensures that your specific requirements for a wooden tricycle for kids can be met with precision and efficiency, leading to a unique product that stands out in the market.

Real-World Application Case Studies

Experience is key to demonstrating product efficacy and reliability. Here are illustrative case studies highlighting the successful implementation of the wooden tricycle for kids in various B2B contexts.

Case Study 1: Large-Scale Educational Procurement

Client: A national chain of 150 early learning centers (kindergartens and daycare facilities).

Challenge: The client required durable, safe, and aesthetically pleasing tricycles for daily use across all their facilities, with an emphasis on sustainable materials and easy maintenance. Previous plastic tricycles had a high breakage rate and faded quickly.

Solution: We supplied 750 units of our premium wooden tricycle for kids (5 per center), customized with their institutional color scheme and logo. The tricycles featured solid rubber wheels for quiet indoor use and reduced floor marking.

Outcome: After 18 months, the client reported a 70% reduction in replacement costs compared to their previous plastic models. Staff appreciated the easy-to-clean surfaces and parents praised the natural, engaging design. The tricycles met all local and international safety standards, ensuring full compliance for their regulated environment.

Case Study 2: Boutique Retail Launch of a vintage kids tricycle Line

Client: A high-end children's furniture and toy boutique with 10 physical stores and an e-commerce platform.

Challenge: The client sought to launch an exclusive line of "heirloom quality" tricycles that aligned with their brand's vintage aesthetic and commitment to craftsmanship. They specifically requested a vintage zenith kids tricycle and a vintage gold kids tricycle look.

Solution: We partnered as an ODM, developing two unique models with specialized finishes (a deep mahogany stain with brass accents for the 'Zenith' and a subtle gold-infused natural wood finish for the 'Gold'). The tricycles incorporated classic design elements while meeting modern safety standards. Initial order was for 200 units per model.

Outcome: The new line became a best-seller, driving significant foot traffic and online engagement. Customer feedback consistently highlighted the unique aesthetic, exceptional build quality, and nostalgic appeal. The client expanded their order by 50% in the subsequent quarter, citing strong market reception and positive brand association.

Ensuring Trust: Quality Assurance, Certifications, and Testing

Trustworthiness in B2B transactions, particularly for children's products, hinges on demonstrable commitment to quality and safety. Our manufacturing processes for the wooden tricycle for kids are underpinned by stringent quality assurance protocols and comprehensive testing regimes.

Authoritative Standards and Certifications:

- ISO 9001: Our manufacturing facilities operate under an ISO 9001 certified Quality Management System, ensuring consistent product quality, operational efficiency, and continuous improvement.

- EN 71 Toy Safety Directive: All our tricycles comply with the European Toy Safety Directive EN 71, covering mechanical and physical properties, flammability, and migration of certain elements.

- ASTM F963: Products destined for the North American market adhere to the ASTM F963 Standard Consumer Safety Specification for Toy Safety, addressing aspects like material quality, hazardous substances, and structural integrity.

- FSC Certification: Our commitment to sustainable sourcing is demonstrated through the use of FSC-certified wood materials, ensuring responsible forest management.

Internal Testing Protocols:

- Load Bearing Tests: Each design undergoes static and dynamic load tests to ensure it can safely support more than its rated weight capacity over extended periods.

- Impact Resistance: Components are subjected to impact tests to simulate real-world falls and collisions, ensuring the structural integrity remains uncompromised.

- Fatigue Testing: Moving parts, such as axles and steering mechanisms, undergo cyclic testing to simulate years of use, confirming long-term durability and performance.

- Surface Coating Adhesion: Finishes are tested for scratch resistance and adhesion, ensuring that non-toxic coatings remain intact even under rigorous play.

This multi-layered approach to quality and safety builds significant trust, assuring B2B partners of reliable, compliant, and market-ready products.

Frequently Asked Questions (FAQ) about wooden tricycle for kids

Q1: What age range is suitable for a wooden tricycle for kids?

A1: Our standard models are typically designed for children aged 12 months to 3 years, with adjustable seat heights to accommodate growth. We also offer specialized designs, such as a two seats kids tricycle, for broader age ranges or multiple riders.

Q2: Are the finishes on your wooden tricycles safe for children?

A2: Absolutely. All finishes, paints, and lacquers used on our wooden tricycle for kids products are water-based, non-toxic, and lead-free. They are rigorously tested and certified to comply with international safety standards such as EN 71-3 (migration of certain elements) and ASTM F963.

Q3: Can I order a customized wooden tricycle for kids with my own branding?

A3: Yes, we offer comprehensive OEM/ODM services. This includes custom branding (logo application), specific color schemes, material choices, and even design modifications to meet your unique product vision, whether you require a vintage gold kids tricycle aesthetic or a modern, minimalist design.

Q4: What is the typical lead time for a wholesale order of wooden tricycles?

A4: Standard lead times for wholesale orders typically range from 30 to 45 days, depending on the order quantity and level of customization. We recommend contacting our sales team with your specific requirements for a precise lead time estimate.

Logistics and Support: Lead Time, Warranty, and Customer Service

Our commitment to B2B partners extends beyond product quality to encompass seamless logistics and robust after-sales support, ensuring a reliable and transparent procurement experience for every wooden tricycle for kids order.

Lead Time and Fulfillment:

- Standard Orders: For standard models of the wholesale kids tricycle, production lead times are generally 30-45 calendar days from confirmed order and deposit.

- Customized Orders: OEM/ODM projects may require 45-60 days, depending on design complexity and tooling requirements.

- Expedited Options: In specific circumstances, expedited production can be discussed for urgent requirements. Please consult with our sales representatives for feasibility and terms.

- Shipping: We facilitate various shipping options, including FOB, CIF, DDP, ensuring flexibility for our global partners. Detailed shipping quotes and transit times are provided upon request.

Warranty Commitments:

We stand by the quality of our wooden tricycle for kids products. All tricycles come with a standard 2-year warranty covering manufacturing defects and structural integrity under normal use. This warranty underscores our confidence in the materials and craftsmanship. Detailed warranty terms are available upon request.

Dedicated Customer Support:

Our dedicated B2B customer support team is available to assist with inquiries, order tracking, technical support, and post-sales assistance. We prioritize clear communication and swift resolution to ensure complete partner satisfaction. Support channels include email, dedicated account managers, and online portals.

Conclusion

The selection of a wooden tricycle for kids represents a strategic investment in durable, safe, and sustainably manufactured children's mobility solutions. As market trends gravitate towards natural materials, ergonomic design, and products that withstand rigorous institutional use, wooden tricycles emerge as a superior choice for B2B procurement across educational, retail, and hospitality sectors. Our commitment to stringent manufacturing processes, adherence to international safety standards, and robust after-sales support ensures that partners receive products that not only meet but exceed expectations in quality, reliability, and market appeal.

References

- European Committee for Standardization. (2019). EN 71-1: Safety of toys - Part 1: Mechanical and physical properties.

- ASTM International. (2022). ASTM F963-23: Standard Consumer Safety Specification for Toy Safety.

- Forest Stewardship Council. (n.d.). FSC Principles and Criteria for Forest Stewardship.

- International Organization for Standardization. (2015). ISO 9001:2015: Quality management systems – Requirements.

- Statista. (2023). Global toy market revenue by segment.

-

The Essential Guide to 16 Inch Child's Bikes – Safety, Specs & Trends

NewsNov.24,2025

-

Kids Road Bike 24 – Lightweight, Safe, and Perfect for Young Cyclists

NewsNov.23,2025

-

Discover Safe and Fun Children's Bikes 14 Inch | Durable Kids' Bikes Reviewed

NewsNov.22,2025

-

Discover the Perfect Little Girl 16 Inch Bike – Safety, Style & Performance

NewsNov.22,2025

-

The Ultimate Guide to 12 Kids Bicycles – Safety, Trends & Top Picks

NewsNov.21,2025

-

14 Inch Children’s Bikes: A Guide to Safety, Durability & Global Impact

NewsNov.20,2025