Aug . 22, 2025 10:20 Back to list

Durable Wooden Tricycle for Kids - Classic & Safe Ride

Advancing Early Childhood Mobility: The Strategic Role of wooden tricycle for kids in B2B Markets

In the rapidly evolving juvenile product market, the demand for durable, sustainable, and developmentally beneficial toys is at an all-time high. For B2B stakeholders, including retailers, educational institutions, and distribution networks, understanding the intrinsic value of a wooden tricycle for kids is paramount. This detailed analysis explores the industry landscape, technical specifications, manufacturing intricacies, and strategic advantages that position wooden tricycles as a superior choice for discerning buyers seeking both quality and long-term value.

The shift towards eco-conscious consumerism has significantly impacted the children's toy sector, driving a preference for products made from natural, non-toxic materials. This trend is not merely aesthetic; it reflects a deeper commitment to child safety and environmental stewardship. Products like the Superior Quality Bike Balance Bicycle, while primarily a balance bike, embodies the same material philosophy and design principles that elevate premium wooden tricycle for kids offerings. This segment delves into the technical superiority and market dynamics that define this product category.

Industry Trends and Market Dynamics

The global children’s toys market is projected to reach USD 166.3 billion by 2027, growing at a CAGR of 4.5% from 2020 to 2027 (Source: Grand View Research). Within this expansive market, the demand for ride-on toys, particularly those that promote physical development and environmental responsibility, is experiencing robust growth. The resurgence of `vintage kids tricycle` designs, often re-engineered with modern safety standards and sustainable materials, highlights a consumer desire for timeless aesthetics combined with contemporary performance.

Key trends influencing the `wholesale kids tricycle` market include:

- Sustainability Focus: Increased consumer preference for eco-friendly materials such as certified wood, recycled plastics, and non-toxic finishes.

- Developmental Benefits: Products that aid in gross motor skill development, balance, and coordination are highly sought after by parents and educators.

- Durability and Longevity: A shift away from disposable plastic toys towards robust products that can withstand extensive use and be passed down, aligning with `vintage zenith kids tricycle` and `vintage gold kids tricycle` aesthetics.

- Safety Certifications: Stringent adherence to international safety standards (e.g., EN71, ASTM F963) is a non-negotiable for B2B buyers.

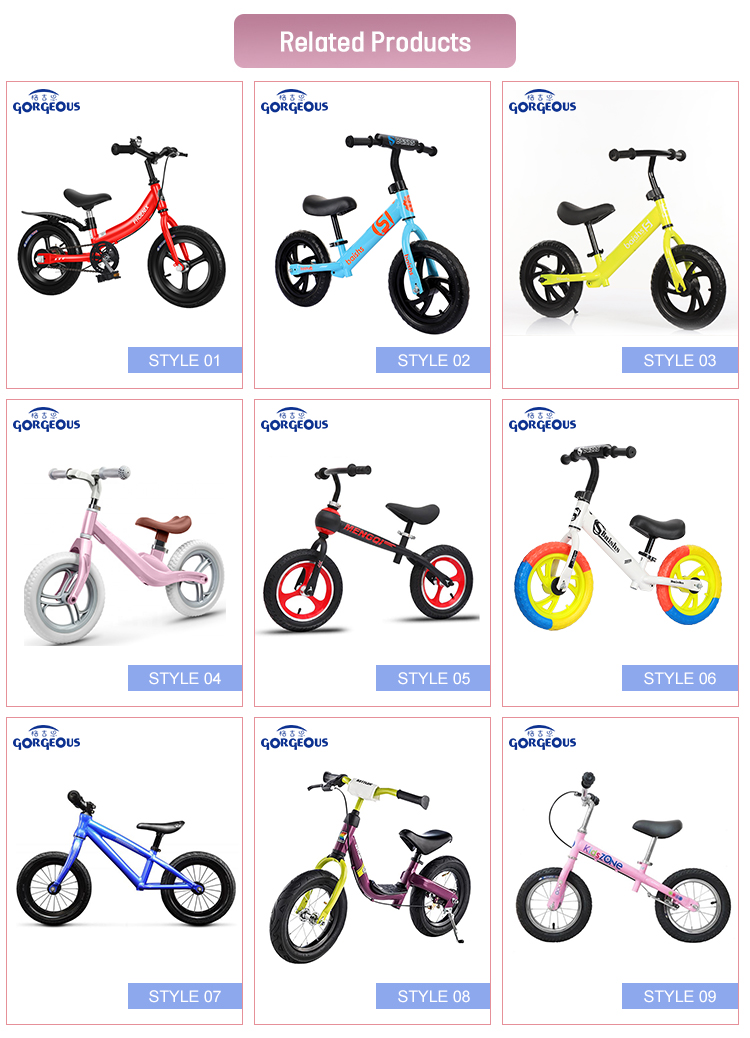

- Customization and Personalization: Opportunities for branding and unique product offerings are becoming crucial for retailers to differentiate themselves.

The niche for `two seats kids tricycle` or `two seater tricycle for kids` is also expanding, catering to families with multiple young children, offering shared play experiences and enhanced utility in educational settings. These trends underscore the strategic importance for B2B entities to partner with manufacturers capable of delivering high-quality, compliant, and market-responsive products.

Manufacturing Process of a High-Quality Wooden Tricycle for Kids

The creation of a premium wooden tricycle for kids is a meticulous process, combining traditional woodworking craftsmanship with modern precision engineering. Our approach emphasizes sustainability, safety, and durability at every stage.

Process Flow:

-

Material Sourcing & Selection:

We exclusively use FSC-certified hardwoods such as Baltic Birch plywood, beech, or rubberwood, known for their strength, stability, and sustainable harvesting practices. These materials offer superior resistance to warping and splintering compared to softer woods. Each timber batch undergoes rigorous inspection for density, moisture content, and freedom from defects.

-

Precision Cutting (CNC Machining):

Raw timber is transferred to advanced CNC (Computer Numerical Control) machining centers. This allows for extremely precise cutting of all components (frame, handlebars, wheels, seat) according to digital blueprints. CNC ensures consistency, minimal material waste, and perfectly interlocking parts, crucial for structural integrity.

-

Sanding and Edge Finishing:

All wooden components undergo multi-stage sanding. Initial coarse sanding removes tool marks, followed by progressively finer grits to achieve an impeccably smooth surface. Edges are meticulously rounded and chamfered to eliminate any sharp points, ensuring maximum safety for children. This step is critical for preventing splinters and enhancing tactile experience.

-

Assembly and Joinery:

Components are assembled using robust, child-safe fasteners and non-toxic, formaldehyde-free glues. Mortise and tenon or dovetail joints are utilized where appropriate to enhance structural strength, ensuring the `two seat tricycle kids` or standard model can withstand vigorous play. Each joint is inspected for tightness and stability.

-

Finishing and Coating:

Finished wooden parts receive multiple coats of non-toxic, water-based paints, varnishes, or natural oils. These finishes comply with EN71-3 (migration of certain elements) and ASTM F963-17 (heavy metals content). This not only protects the wood but also adds to the aesthetic appeal and ensures child safety from harmful chemicals.

-

Quality Control and Testing:

Each wooden tricycle for kids undergoes a battery of tests to ensure compliance with international safety standards such as ISO 8124, ASTM F963, and European standard EN71. This includes mechanical strength tests (impact, compression, static load), chemical analysis of finishes, and small parts/choking hazard assessments. Our internal QA process is aligned with ISO 9001 quality management principles.

-

Packaging and Distribution:

Products are carefully packaged using recyclable materials to prevent damage during transit. Detailed assembly instructions and safety warnings are included. Our logistics network ensures efficient and timely delivery to `wholesale kids tricycle` partners globally.

Service Life and Target Industries:

The robust construction and high-quality materials guarantee an extended service life, often exceeding 5-7 years even under heavy institutional use. This longevity reduces replacement costs and environmental impact.

Target industries and application scenarios include:

- Specialty Toy Retailers: Offering premium, sustainable options to discerning consumers.

- Early Childhood Education Centers (ECEC) & Kindergartens: Durable, safe, and developmentally appropriate ride-on toys for collective play.

- Online Retailers & Marketplaces: Meeting the growing demand for eco-friendly and high-quality children's products.

- Hotel & Resort Kids' Clubs: Providing engaging and safe play equipment for young guests.

Technical Specifications and Performance Parameters

Understanding the technical parameters of a wooden tricycle for kids is crucial for B2B buyers to assess quality, safety, and suitability for their target markets. Our products are engineered to exceed baseline industry requirements.

Typical Product Specifications (Example based on premium wooden balance/tricycle designs):

| Parameter | Specification | Compliance/Standard |

|---|---|---|

| Frame Material | FSC-certified Baltic Birch Plywood (12-15mm thickness) | ISO 9001 Material Sourcing |

| Wheel Type | Solid Rubber Tires (puncture-proof) with sealed bearings | ASTM F963-17 (Durability), EN71 (Mechanical) |

| Finish/Paint | Non-toxic, water-based, lead-free (multiple coats) | EN71-3, CPSIA (Lead & Phthalates) |

| Recommended Age | 12 months to 4 years (adjustable seat height) | Age Grading per EN71, ASTM F963 |

| Max Load Capacity | Typically 25-30 kg (55-66 lbs) | Static Load Test per ISO 8124-1 |

| Product Weight | 2.5 - 4.0 kg (5.5 - 8.8 lbs) | Design Specification |

| Adjustable Seat Height | 3-5 positions, range 22-30 cm | Ergonomic Design |

| Steering Mechanism | Limited steering angle (e.g., 30 degrees) to prevent jackknifing | Safety Feature per EN71-1 |

These specifications ensure not only the immediate safety of the child but also the long-term structural integrity and performance, critical for environments with high usage rates like daycare centers.

Technical Advantages and Application Scenarios

The inherent characteristics of a well-designed wooden tricycle for kids offer distinct advantages over plastic or metal alternatives, making them ideal for various B2B applications.

Key Technical Advantages:

- Superior Durability: Solid wood construction and expert joinery provide exceptional strength, withstanding impacts and prolonged use without cracking or deforming, unlike many plastic variants. This results in significantly lower replacement rates for institutions.

- Environmental Sustainability: Sourced from renewable forests (FSC-certified) and biodegradable at end-of-life, wooden tricycles have a lower carbon footprint compared to petroleum-derived plastics.

- Enhanced Child Safety: Natural materials, non-toxic finishes, smooth edges, and carefully engineered designs minimize risks of chemical exposure, choking hazards, and physical injury. Self-limiting steering angles prevent over-steering and falls.

- Aesthetic and Sensory Appeal: The natural grain and warmth of wood offer a tactile and visually appealing experience, fostering a connection with natural materials. This aesthetic integration is highly valued in modern educational and retail environments, especially for products like `vintage kids tricycle`.

- Developmental Efficacy: The weight and stable structure provide optimal feedback for developing motor skills, balance, and coordination. The simplicity of design encourages imaginative play and focus.

Typical Application Scenarios:

-

Early Learning Centers & Preschools:

Wooden tricycles are integral to outdoor play areas, supporting physical education curricula. Their robustness ensures they can endure daily use by multiple children, and their natural aesthetic aligns with Montessori and Waldorf educational philosophies.

-

Specialty Toy Stores:

For retailers aiming to offer high-end, eco-conscious, and pedagogically sound products, wooden tricycles represent a premium segment. Products like `two seater kids tricycle` offer unique selling propositions.

-

Online Juvenile Product Marketplaces:

Online platforms benefit from the high perceived value and strong SEO potential of sustainable wooden toys, attracting a growing segment of environmentally aware parents.

-

Resort and Hotel Chains (Kids' Clubs):

High-traffic play areas demand robust and aesthetically pleasing equipment. Wooden tricycles align with premium branding and offer reliable performance.

Vendor Comparison and Customization Solutions

Selecting the right manufacturing partner for `wholesale kids tricycle` orders is critical. A robust vendor comparison considers not just price, but quality, certifications, customization capabilities, and after-sales support.

Key Differentiators in Vendor Selection:

| Feature | Our Offering | Typical Competitor (Lower Tier) |

|---|---|---|

| Material Sourcing | FSC-certified hardwoods, verified non-toxic | Unspecified wood/MDF, potential for formaldehyde |

| Manufacturing Process | CNC precision, multi-stage sanding, robust joinery | Manual cutting, basic sanding, staple/screw assembly |

| Safety Certifications | EN71, ASTM F963, CPSIA (regularly updated) | Minimal or outdated certifications, self-declared |

| Finish Quality | Multi-layer, chip-resistant, compliant non-toxic paints | Single-layer, prone to chipping, unverified chemical content |

| Customization | Extensive (colors, branding, design modifications) | Limited to standard colors or basic logo prints |

| Warranty & Support | Comprehensive warranty, dedicated B2B support | Short warranty, limited support availability |

Customized Solutions for B2B Clients:

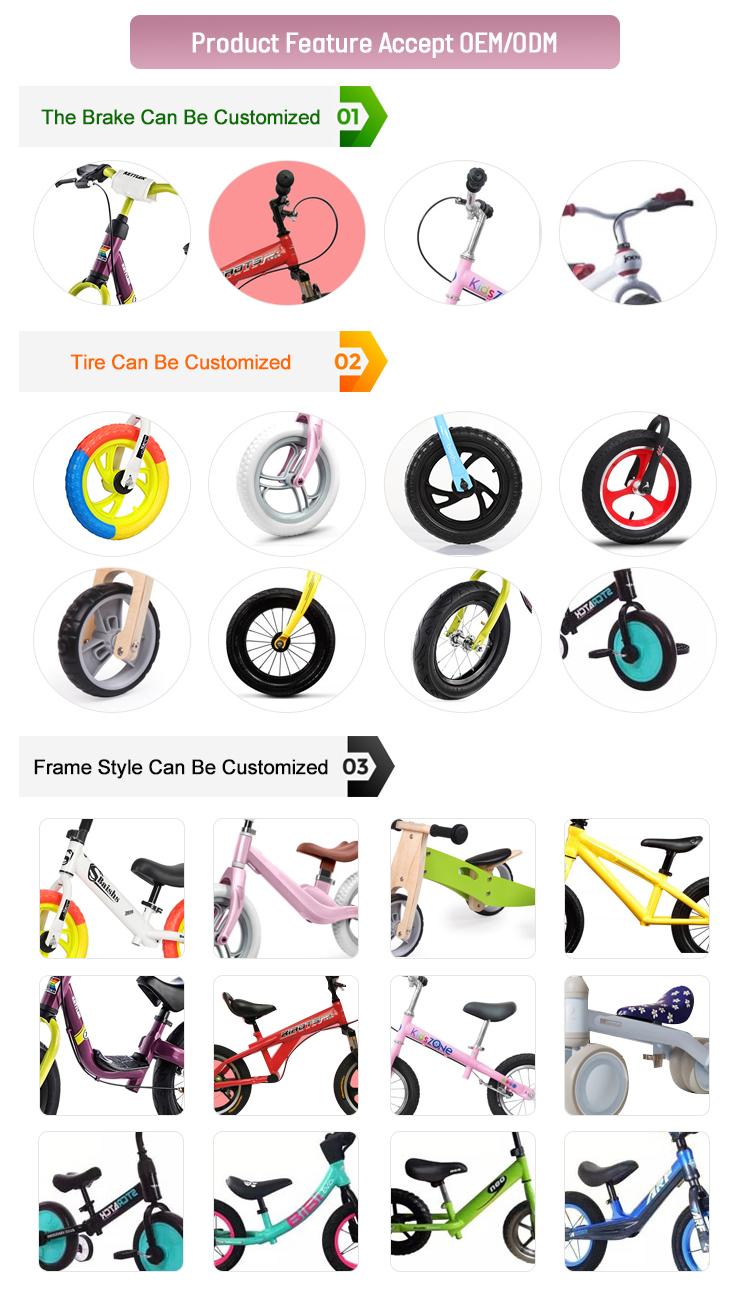

We understand that B2B partners often require specific adaptations to meet their market demands. Our capabilities for customization include:

- Brand Integration: Incorporating client logos via engraving, screen printing, or customized decals on any wooden tricycle for kids model.

- Color Schemes: Tailoring paint and finish colors to align with corporate branding or specific seasonal collections.

- Design Modifications: Adapting existing designs for features like adjustable seats, additional storage, or specialized wheel configurations (e.g., for `two seater tricycle for kids` or specific terrain use).

- Packaging Solutions: Custom packaging options, including private label branding, multi-packs for `wholesale kids tricycle` orders, or retail-ready displays.

- Material Alternatives: Exploring alternative certified wood types or hybrid material constructions to meet specific aesthetic or functional requirements.

Application Case Studies and Customer Experience

Real-world application demonstrates the tangible benefits and superior performance of our wooden tricycles. These case studies highlight our commitment to quality and client satisfaction.

Case Study 1: Large Educational Toy Distributor

Client: EduPlay Solutions, a leading distributor to early learning centers across Europe.

Challenge: EduPlay needed a reliable supplier for durable, compliant, and aesthetically pleasing ride-on toys to replace their existing plastic models, which suffered from high breakage rates and limited educational appeal.

Solution: We supplied a range of customized wooden tricycle for kids models, including a `two seater kids tricycle` variant. All units featured reinforced joints and an anti-tip steering mechanism. Our ISO 8124 and EN71 certifications were crucial for their procurement standards.

Results: Over a 24-month period, EduPlay reported a 70% reduction in product returns due to damage. Customer feedback from kindergartens highlighted improved child engagement, greater longevity, and a preferred natural aesthetic. This led to a 3-year exclusive supply agreement.

Case Study 2: Boutique Online Retailer (Vintage Segment)

Client: "Timeless Tots," an online store specializing in high-quality, `vintage kids tricycle` and classic children's products.

Challenge: Timeless Tots sought a manufacturer capable of producing wooden tricycles that replicated a `vintage zenith kids tricycle` aesthetic while meeting modern safety standards and utilizing sustainable materials.

Solution: We developed a bespoke line of wooden tricycles with custom paint finishes and a classic design profile. Our ability to provide detailed material provenance (FSC-certified wood) and non-toxic finish declarations (CPSIA compliant) was key.

Results: The `vintage gold kids tricycle` line became a best-seller, driving a 45% increase in traffic to Timeless Tots' ride-on category. Customer reviews consistently praised the authentic vintage feel, robust build quality, and commitment to safety, affirming our expertise in delivering specialized B2B solutions.

Trustworthiness: FAQ, Lead Time, Warranty, and Support

Frequently Asked Questions (FAQ):

Q: Are your wooden tricycles certified for safety?

A: Absolutely. All our products, including the wooden tricycle for kids, meet or exceed international safety standards such as EN71 (European), ASTM F963 (USA), and ISO 8124 (International). We provide all relevant certification documents upon request.

Q: What materials are used, and are they sustainable?

A: We primarily use FSC-certified Baltic Birch plywood or similar sustainable hardwoods. All paints and finishes are water-based, non-toxic, and free from heavy metals, complying with EN71-3 and CPSIA regulations.

Q: Can we customize the design or add our brand logo?

A: Yes, we offer extensive customization options, including bespoke color schemes, engraving or printing client logos, and even minor design modifications for `wholesale kids tricycle` orders. Please contact our B2B sales team to discuss your specific requirements.

Q: What is the typical lead time for a bulk order?

A: Lead times vary based on order volume and customization complexity. For standard `wholesale kids tricycle` orders, typical lead time is 30-45 days after deposit and design approval. Customized orders may require 45-60 days. We provide precise timelines upon order confirmation.

Lead Time & Fulfillment Details:

Our streamlined production process and established logistics network ensure efficient order fulfillment. We maintain strong relationships with global shipping partners to offer competitive freight options, whether DDP (Delivered Duty Paid) or EXW (Ex Works), based on client preference. We provide regular updates throughout the production and shipping phases.

Warranty Commitments:

We stand by the quality of our products with a comprehensive 1-year limited warranty against manufacturing defects for all wooden tricycle for kids units. This warranty covers structural integrity and material flaws under normal use conditions. For commercial or institutional clients, extended warranty options may be available.

Customer Support Information:

Our dedicated B2B customer support team is available to assist with inquiries, order tracking, technical support, and after-sales service. We pride ourselves on responsive and professional communication to ensure a seamless partnership.

Contact Email: sales@gorgeousbike.com

Phone: [Insert B2B Phone Number Here - e.g., +1-XXX-XXX-XXXX]

Business Hours: Monday - Friday, 9:00 AM - 5:00 PM (GMT+8)

Conclusion

The strategic procurement of a wooden tricycle for kids represents a forward-thinking investment for B2B entities. Beyond their aesthetic appeal and developmental benefits, these products offer unparalleled durability, environmental responsibility, and adherence to the most stringent safety standards. By partnering with a manufacturer committed to precision engineering, sustainable sourcing, and comprehensive customer support, businesses can confidently meet evolving market demands and deliver superior value to their end-users. Our expertise in crafting high-quality, customizable wooden tricycles positions us as an ideal partner for `wholesale kids tricycle` distributors, educational suppliers, and retailers looking to elevate their product offerings in a competitive global market.

References

- Grand View Research. (2020). Children Toys Market Size, Share & Trends Analysis Report By Product, By Age Group, By Distribution Channel, By Region, And Segment Forecasts, 2020 - 2027.

- Forest Stewardship Council (FSC). (n.d.). About FSC. Retrieved from https://fsc.org/en

- European Committee for Standardization (CEN). (2011). EN 71 Safety of toys - Part 1: Mechanical and physical properties.

- ASTM International. (2017). ASTM F963-17: Standard Consumer Safety Specification for Toy Safety.

- International Organization for Standardization (ISO). (2014). ISO 8124-1: Safety of toys - Part 1: Safety aspects related to mechanical and physical properties.

- U.S. Consumer Product Safety Commission (CPSC). (2008). Consumer Product Safety Improvement Act (CPSIA).

-

The Essential Guide to 16 Inch Child's Bikes – Safety, Specs & Trends

NewsNov.24,2025

-

Kids Road Bike 24 – Lightweight, Safe, and Perfect for Young Cyclists

NewsNov.23,2025

-

Discover Safe and Fun Children's Bikes 14 Inch | Durable Kids' Bikes Reviewed

NewsNov.22,2025

-

Discover the Perfect Little Girl 16 Inch Bike – Safety, Style & Performance

NewsNov.22,2025

-

The Ultimate Guide to 12 Kids Bicycles – Safety, Trends & Top Picks

NewsNov.21,2025

-

14 Inch Children’s Bikes: A Guide to Safety, Durability & Global Impact

NewsNov.20,2025