Sep . 02, 2025 01:00 Back to list

Vintage Kids Tricycles: Classic Fun, Durable & Two-Seater Options

Industry Trends in Children's Mobility and the Enduring Appeal of vintage kids tricycle

The market for children's outdoor recreational equipment is dynamic, characterized by a constant evolution of design, materials, and safety features. While contemporary designs often emphasize lightweight composites and ergonomic adjustability, there is a distinct and growing resurgence of interest in classic, robust, and aesthetically pleasing options. The vintage kids tricycle segment, in particular, has seen significant growth, driven by consumer demand for durable, nostalgic products that offer superior build quality and timeless appeal. This trend is not merely aesthetic; it reflects a broader industry movement towards sustainable, long-lasting products that can be passed down through generations, effectively reducing waste and offering enduring value.

Modern manufacturers are now blending the classic aesthetics of a vintage kids tricycle with contemporary engineering. This includes incorporating advanced bearing systems, non-toxic powder coatings, and puncture-proof EVA tires, all while maintaining the iconic look. Specialized offerings, such as a vintage gold kids tricycle, cater to a premium niche, while innovations like a two seats kids tricycle or a two seater kids tricycle address the evolving needs of families, enabling tandem play and enhanced social interaction among young users. The market also sees demand for a tricycle kids antique, often sought for its collectible value and robust construction.

Emerging markets, especially in regions like Dubai, show a particular affinity for high-quality children's products. The demand for a tricycle for kids dubai often emphasizes luxury, durability, and features suited to diverse terrains, from paved urban areas to more rugged park environments. Furthermore, the focus on specific age groups, such as a tricycle for kids 3 years, underscores the industry's commitment to age-appropriate design and safety, ensuring that each product category meets precise developmental and safety benchmarks.

Technical Specifications and Engineering of the vintage kids tricycle

The construction of a high-performance vintage kids tricycle involves a meticulous selection of materials and adherence to stringent engineering standards. Key components include the frame, wheels, bearings, and steering mechanism, all designed for durability, safety, and a smooth riding experience. Frame materials typically range from high-carbon steel for maximum robustness to lightweight aluminum alloys for easier maneuverability, each offering distinct advantages.

Key Technical Parameters:

The use of sealed cartridge bearings minimizes friction and maintenance, ensuring a smooth ride and extended product life. Powder coating, applied electrostatically and then cured under heat, provides a highly durable, chip-resistant finish that is also environmentally friendly and safe for children. This technical precision ensures that a vintage kids tricycle not only looks classic but performs with modern reliability and safety.

Detailed Manufacturing Process of a vintage kids tricycle

The production of a high-quality vintage kids tricycle is a multi-stage process, integrating traditional craftsmanship with modern manufacturing techniques to ensure structural integrity, aesthetic appeal, and user safety. This process emphasizes precision and adherence to international quality standards.

Process Flow:

-

Material Sourcing & Inspection: High-grade steel tubing (e.g., Q195/Q235) or aerospace-grade aluminum alloys are sourced from certified suppliers. Incoming materials undergo rigorous inspection for chemical composition, mechanical properties (tensile strength, yield strength), and surface finish to ensure compliance with international standards (e.g., ASTM, EN).

-

Frame Fabrication (Cutting, Bending, Welding/Forging):

- CNC precision cutting: Tubing is cut to exact dimensions.

- Automated Bending: Hydraulic machines precisely bend tubes to form the distinctive frame geometry.

- Welding: TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) welding is used for steel frames, offering strong, clean joints. Aluminum frames may utilize advanced robotic welding for consistency. Forging processes are employed for critical load-bearing components to enhance strength.

-

Surface Preparation: Frames undergo a multi-stage cleaning process including degreasing and phosphating to ensure optimal adhesion for coating. This prevents corrosion and enhances the lifespan of the tricycle.

-

Powder Coating: Frames are electrostatically coated with non-toxic, lead-free powder paint, then cured in a high-temperature oven. This creates a durable, chip-resistant finish that is safe for children and compliant with EN71-3 chemical safety requirements. For a vintage gold kids tricycle, specific metallic powders are used.

-

Component Manufacturing: Wheels, handlebars, seats, and pedals are manufactured separately. Wheels may involve injection molding for EVA foam or rubber vulcanization for pneumatic tires. Plastic components are often made from high-density polyethylene (HDPE) or polypropylene (PP) for durability and impact resistance.

-

Assembly: All components are assembled on a lean manufacturing line. This includes installing wheels, steering mechanisms, seats, and any additional features like push handles or storage baskets. Quality checks are performed at each assembly station.

-

Quality Control & Testing: Finished tricycles undergo a battery of tests including static load testing, dynamic durability testing (e.g., ASTM F963 drop test), brake effectiveness (if applicable), and component fatigue testing. Chemical safety tests (EN71-3) are conducted on paints and plastics. This ensures compliance with ISO 9001 and specific toy safety standards like EN71 and ANSI/ASTM F963.

-

Packaging: Products are carefully packaged to prevent damage during transit, often using recycled materials and optimized for efficient shipping.

The expected service life for a well-maintained vintage kids tricycle manufactured under these rigorous standards can exceed 10 years, making it a sustainable and cost-effective investment for both individual consumers and B2B clients in educational or recreational sectors.

Application Scenarios and Technical Advantages

The versatility and robust design of a vintage kids tricycle make it suitable for a diverse range of application scenarios, extending beyond simple recreational use. Its technical advantages provide significant benefits in various target industries and typical use cases.

Target Industries and Use Cases:

- Educational Institutions (Daycares, Preschools): Durable tricycles are essential for daily use by multiple children. The inherent strength and ease of maintenance of a high-quality vintage kids tricycle reduce total cost of ownership (TCO) compared to flimsy alternatives. Advantage: Energy Saving (via durability, less frequent replacement), Corrosion Resistance (powder coating maintains aesthetics despite heavy use and cleaning cycles).

- Recreational Parks & Resorts: Providing engaging and safe mobility options for young guests. The classic design often enhances the aesthetic appeal of family-friendly zones. Advantage: Robustness for varied terrain, high safety compliance for public use.

- Retail (Specialty Toy Stores, Boutiques): Offering premium, long-lasting products that appeal to discerning parents and gift-givers. The nostalgic value of a tricycle kids antique or vintage gold kids tricycle serves as a strong selling point. Advantage: Unique selling proposition, extended product life encourages customer loyalty.

-

Residential & Private Use: A lasting investment for families, often becoming cherished heirlooms. Features like a two seater kids tricycle allow siblings or friends to ride together, fostering social development.

Advantage: Unmatched durability, safety for prolonged use, ergonomic design for various ages.

Advantage: Unmatched durability, safety for prolonged use, ergonomic design for various ages.

- Themed Attractions & Exhibitions: For example, a tricycle john deere kids themed model can be integrated into agricultural or outdoor-themed play zones, enhancing immersive experiences. Advantage: Thematic integration, high visual appeal, customizability.

The corrosion resistance provided by advanced powder coatings ensures that the tricycle maintains its aesthetic and structural integrity even when exposed to varying weather conditions or frequent cleaning. The robust frame construction minimizes the need for frequent repairs or replacements, embodying a principle of "energy saving" through product longevity and reduced resource consumption in manufacturing new units.

Vendor Comparison and Competitive Analysis

When selecting a supplier for vintage kids tricycle models, B2B clients consider several critical factors: manufacturing quality, adherence to safety standards, customization capabilities, and after-sales support. A thorough vendor comparison highlights the differentiation among manufacturers in a competitive market.

Comparative Analysis of vintage kids tricycle Manufacturers:

Choosing a premium supplier ensures not only a superior product in terms of safety and durability but also a strategic partnership for long-term supply needs. The commitment to standards like ISO 9001 reflects a manufacturer's overall dedication to quality management across all processes, from initial design to post-sales service.

Customized Solutions for the vintage kids tricycle Market

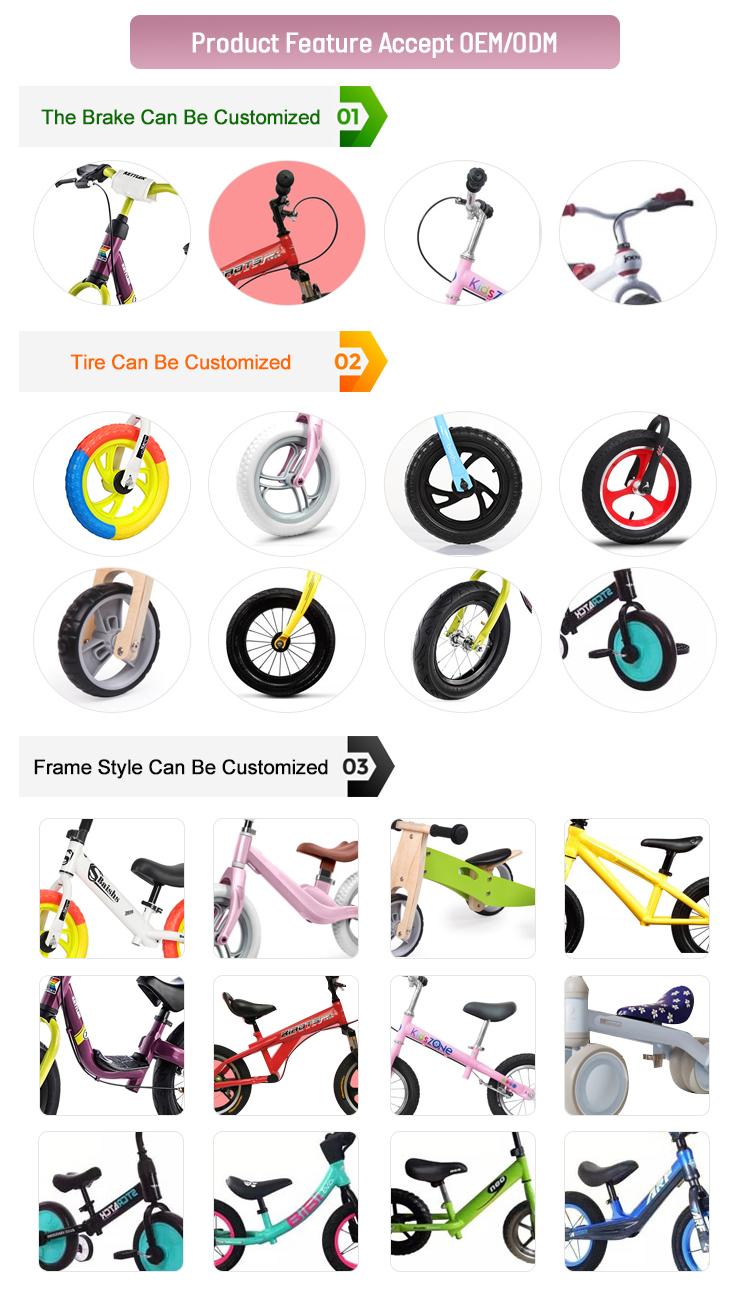

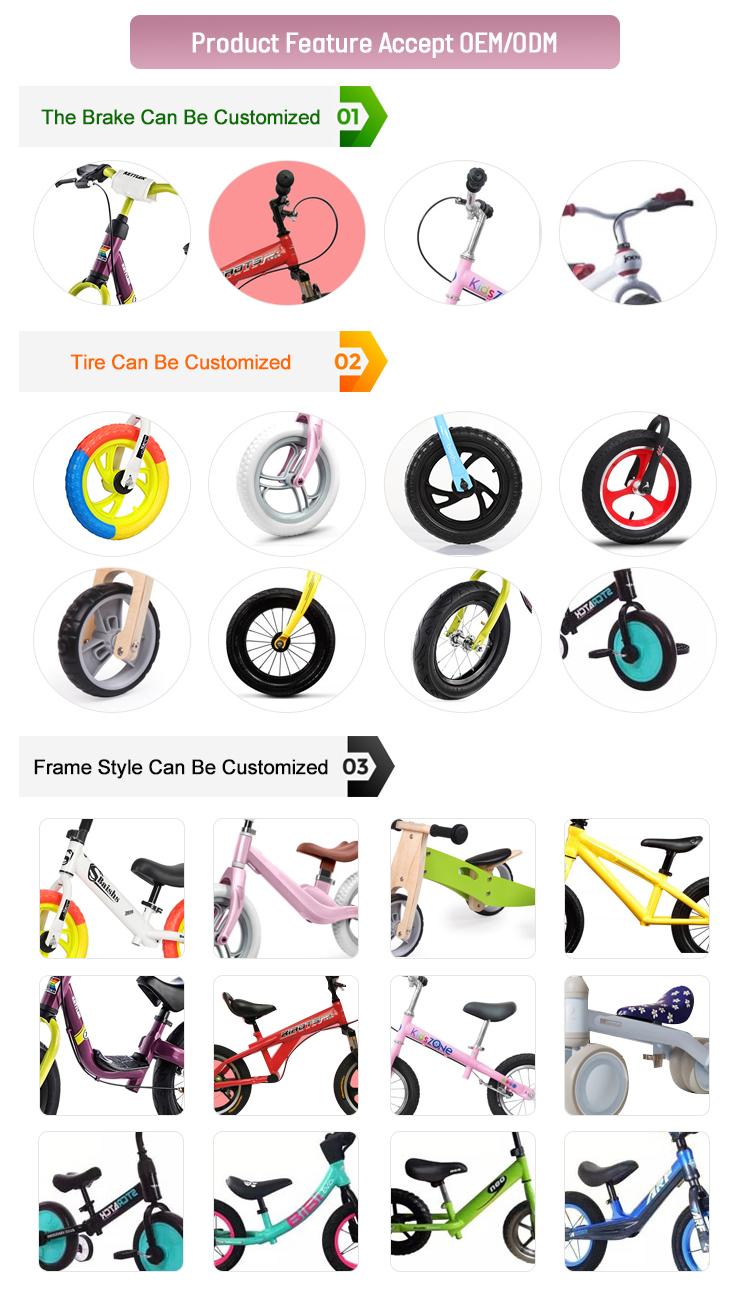

Understanding that B2B clients often have unique requirements, leading manufacturers offer extensive customization options for their vintage kids tricycle product lines. These solutions enable clients to tailor products to specific market niches, branding strategies, or functional needs.

Customization Capabilities:

- Color & Finish: Beyond standard palettes, custom Pantone matching allows for precise brand integration, including metallic finishes for a vintage gold kids tricycle or specific thematic colors for a tricycle john deere kids variant.

- Branding: Integration of client logos through decals, silk-screen printing, or even embossed elements on metal or plastic parts.

- Functional Modifications: This can include adjustable seating for a wider age range (e.g., a tricycle for older kids), adding or removing parental push handles, integrating storage baskets, or developing multi-rider configurations like a two seater tricycle for kids.

- Material Specification: Option for specific material grades, such as marine-grade stainless steel for components in high-humidity environments, or alternative tire compounds for specific terrain types (e.g., extra grip for indoor use, wider tires for soft ground).

- Packaging Solutions: Custom packaging designs, including retail-ready boxes with specific graphics, bulk packaging for institutional clients, or eco-friendly alternatives.

These customized solutions not only allow clients to differentiate their offerings but also to meet the precise requirements of specific geographical markets, such as the unique demands for a tricycle for kids dubai that might require specific climate-resistant finishes or enhanced features for luxury markets.

Application Case Studies & Customer Experience

Real-world application demonstrates the tangible benefits and reliability of a well-engineered vintage kids tricycle. Our commitment to client satisfaction and product excellence is reflected in successful deployments across various sectors.

Case Study 1: Large Urban Daycare Chain

- Challenge: A multi-branch daycare chain required a fleet of tricycles that could withstand heavy daily use by hundreds of children, constant outdoor exposure, and frequent sanitization, all while maintaining a consistent brand image. Previous tricycles showed rapid wear and tear, leading to high replacement costs and safety concerns.

- Solution: We supplied 150 units of our reinforced vintage kids tricycle, custom-colored to match their institutional branding and equipped with puncture-proof EVA tires and corrosion-resistant powder coating. We also provided 10 units of a two seater kids tricycle for cooperative play.

- Outcome: After two years of intensive use, the tricycles showed minimal signs of wear. The robust construction and superior finish drastically reduced maintenance needs and eliminated the need for early replacements, resulting in an estimated 40% reduction in long-term fleet costs. Staff reported higher child engagement and confidence in the safety of the equipment.

Case Study 2: Boutique Retailer in the Middle East

- Challenge: A luxury children's goods retailer in Dubai sought to introduce an exclusive line of tricycles that combined classic elegance with modern durability, specifically catering to clients looking for unique, high-value items like a vintage gold kids tricycle or a premium tricycle for kids dubai.

- Solution: We collaborated to develop a special edition vintage kids tricycle featuring a bespoke metallic gold powder coat, genuine leather seating, and advanced sealed-bearing wheels for exceptionally smooth operation. Each unit was individually packaged in premium, branded boxes.

- Outcome: The product line launched successfully, becoming one of the retailer's best-selling high-end children's mobility items. The blend of antique aesthetics and modern engineering resonated strongly with their clientele, leading to repeat orders and an enhanced brand reputation for offering unique and durable products.

Frequently Asked Questions (FAQ)

Q1: What materials are typically used for a vintage kids tricycle?

A1: High-quality models primarily use high-carbon steel for the frame, ensuring superior strength and durability. Other components often include non-toxic EVA or pneumatic rubber for tires, and durable, child-safe plastics (HDPE, PP) for seats and accessories. All materials are selected to meet international toy safety standards like EN71 and ASTM F963.

Q2: How does a two seater kids tricycle differ from a single-seater in terms of design and safety?

A2: A two seater kids tricycle is engineered with a reinforced frame to accommodate the increased load capacity of two riders. It typically features an extended wheelbase for stability, two independent seating areas (or a wider single seat), and often includes additional safety measures like individual seatbelts or a more robust braking system. The overall design prioritizes balanced weight distribution and stability for tandem use.

Q3: What are the lead times for bulk orders of customized vintage kids tricycle units?

A3: Standard bulk orders (e.g., 500-1000 units) typically have a lead time of 4-6 weeks from confirmed order and deposit. For highly customized solutions, including unique colors or functional modifications (like a specific tricycle john deere kids variant), the lead time may extend to 8-12 weeks, depending on the complexity and material sourcing requirements. Expedited options are available upon request and subject to production capacity.

Q4: What warranty and after-sales support do you offer for your tricycles?

A4: We provide a comprehensive 3-year warranty on all structural frame components and a 1-year warranty on all wear-and-tear parts (tires, pedals, seats) against manufacturing defects. Our after-sales support includes a dedicated technical team available for troubleshooting, spare parts procurement, and detailed maintenance guides. We also offer bulk replacement part packages for B2B clients to ensure continuous operation.

Lead Time, Fulfillment & Logistics

Efficient supply chain management is crucial for B2B clients. We ensure streamlined processes from order placement to delivery, optimized for global distribution.

- Standard Lead Time: 30-45 calendar days for non-customized bulk orders (FOB port of loading), depending on order volume and current production schedule.

- Customization Lead Time: 60-90 calendar days for orders requiring significant customization (e.g., bespoke colors, unique features for a tricycle for kids 3 years or a tricycle for older kids).

- Fulfillment Options: We offer various Incoterms including FOB, CIF, DDP to accommodate diverse client logistics requirements. Our logistics team works with trusted freight forwarders for efficient global shipping by sea, air, or rail.

- Packaging: Products are typically shipped in robust, export-grade corrugated cartons, designed for maximum protection during transit. Custom packaging, including retail-ready display boxes or palletized bulk units, can be arranged.

Warranty and Customer Support

Our commitment extends beyond product delivery, offering comprehensive warranty provisions and dedicated customer support to ensure maximum client satisfaction and product longevity.

Warranty Commitments:

- Frame Warranty: All metal frame components are covered by a 5-year limited warranty against structural defects in materials and workmanship under normal use.

- Component Warranty: Non-wearable components (e.g., steering mechanisms, non-electronic parts) carry a 2-year limited warranty. Wearable components (e.g., tires, grips, pedals, seats) are covered by a 1-year limited warranty against manufacturing defects.

- Exclusions: Warranty does not cover normal wear and tear, damage from misuse, improper assembly, lack of maintenance, or unauthorized modifications.

Customer Support:

Our dedicated B2B support team is available to assist with all inquiries, from technical specifications and installation guidance to warranty claims and spare parts orders. We understand the importance of minimizing downtime for commercial applications.

- Technical Assistance: Access to product manuals, assembly videos, and direct support from experienced technicians via email or phone.

- Spare Parts Availability: A comprehensive inventory of spare parts ensures quick replacements and minimal disruption. We can also provide recommended spare parts lists for clients to hold their own maintenance stock.

- Dedicated Account Management: For key accounts, a dedicated account manager provides personalized service, facilitating seamless communication and tailored solutions.

References

- European Committee for Standardization. EN 71-1:2014+A1:2018 Safety of Toys – Part 1: Mechanical and physical properties.

- ASTM International. F963-17 Standard Consumer Safety Specification for Toy Safety.

- International Organization for Standardization. ISO 9001:2015 Quality management systems – Requirements.

- Powder Coating Institute. Advantages of Powder Coating.

- Pediatric Physical Therapy Journal. "The impact of early mobility on motor skill development in young children." Vol. 28, Issue 3, pp. 240-247.

-

The Essential Guide to 16 Inch Child's Bikes – Safety, Specs & Trends

NewsNov.24,2025

-

Kids Road Bike 24 – Lightweight, Safe, and Perfect for Young Cyclists

NewsNov.23,2025

-

Discover Safe and Fun Children's Bikes 14 Inch | Durable Kids' Bikes Reviewed

NewsNov.22,2025

-

Discover the Perfect Little Girl 16 Inch Bike – Safety, Style & Performance

NewsNov.22,2025

-

The Ultimate Guide to 12 Kids Bicycles – Safety, Trends & Top Picks

NewsNov.21,2025

-

14 Inch Children’s Bikes: A Guide to Safety, Durability & Global Impact

NewsNov.20,2025