Sep . 09, 2025 20:00 Back to list

Classic Wooden Tricycle for Kids - Two Seats, Safe Fun!

Understanding the Market Dynamics of Children's Tricycles

The global market for children's recreational vehicles is experiencing significant growth, driven by increasing parental awareness of child development and the demand for sustainable, durable, and safe play equipment. Within this expanding sector, the demand for a wooden tricycle for kids has seen a notable surge. This is primarily attributed to its eco-friendly attributes, classic aesthetics, and inherent safety features derived from natural materials. Manufacturers and B2B buyers are increasingly prioritizing products that align with contemporary ecological standards and offer long-term value in educational and retail environments.

Key market drivers include the push for non-plastic alternatives, enhanced safety regulations for children's products (e.g., EN 71, ASTM F963), and the rising popularity of Montessori-inspired educational toys. This strategic shift is influencing product development, material selection, and manufacturing processes across the industry. Furthermore, the market is diversifying to include specialized variants such as the two seats kids tricycle, catering to families with multiple children, and the robust tricycle for older kids, designed for extended usability and greater weight capacity.

Manufacturing Process of Premium Wooden Tricycles

The production of a high-quality wooden tricycle for kids is a meticulous process, combining traditional craftsmanship with modern engineering. It emphasizes precision, material integrity, and adherence to stringent safety standards. The typical process flow involves several critical stages, ensuring a product that is both aesthetically pleasing and structurally sound.

1. Material Selection and Preparation

- Wood Sourcing: Premium wood species such as Baltic Birch plywood, beechwood, or rubberwood are selected for their strength, durability, and sustainable harvesting practices. These materials offer superior resistance to impact and wear.

- Drying and Curing: Timber undergoes kiln-drying to achieve optimal moisture content (typically 6-8%). This prevents warping, cracking, and ensures dimensional stability, crucial for the product's longevity and safety.

- Lamination/Bonding: For plywood components, multiple thin veneers are bonded together using formaldehyde-free, child-safe adhesives under high pressure, enhancing structural integrity and reducing splintering risk.

2. Precision Machining and Shaping

- CNC Machining: Computer Numerical Control (CNC) routers are employed for precise cutting, shaping, and drilling of wooden components. This ensures high accuracy, repeatability, and smooth, consistent edges, vital for safety and assembly. Tolerances are typically maintained within ±0.1mm.

- Sanding and Finishing: All wooden surfaces are meticulously sanded to remove imperfections and create a smooth finish, preventing splinters. Multiple stages of sanding, from coarse to fine grits, are performed.

- Edge Rounding: Critical edges are rounded (radiused) to prevent injury, adhering to toy safety standards.

3. Surface Treatment and Finishing

- Non-Toxic Coatings: Components receive multiple coats of child-safe, non-toxic, water-based paints or varnishes. These coatings comply with EN 71-3 (migration of certain elements) and ASTM F963 standards, providing durability and aesthetic appeal without health risks.

- UV Curing: Some finishes may be UV-cured for increased hardness, scratch resistance, and faster production cycles.

4. Assembly and Integration

- Hardware Integration: Non-wooden components, such as solid rubber tires, metal axles, and steering mechanisms, are integrated. Fasteners are typically recessed and secured with child-proof locking mechanisms.

- Ergonomic Design: Assembly adheres to ergonomic principles for children, ensuring comfortable seating, appropriate handle height, and safe steering angles.

5. Quality Control and Testing

- Batch Testing: Each production batch undergoes rigorous testing including impact resistance, drop tests, load-bearing capacity, and stability tests.

- Chemical Analysis: Regular checks for phthalates, lead, and other restricted substances are performed in independent laboratories to ensure compliance with global safety standards like ISO 8124 and CPSIA.

- Service Life: Designed for an estimated service life of 5-10 years under typical household or institutional use, due to the inherent durability of wood and robust construction.

- Target Industries: Wooden tricycles find extensive application in early childhood education centers, daycare facilities, pediatric therapy clinics, and high-end retail sectors focusing on sustainable and quality children's products. They offer advantages such as energy saving in manufacturing (compared to plastic injection molding), and natural corrosion resistance due to the wood's inherent properties and protective finishes.

Technical Specifications and Performance Metrics

The technical specifications of a wooden tricycle are critical for B2B buyers evaluating product performance, safety, and suitability for their target markets. These parameters ensure compliance with international toy safety standards and offer insights into product durability and user experience.

Standard Wooden Tricycle Specifications

| Parameter | Specification Range | Compliance/Standard |

|---|---|---|

| Frame Material | FSC-certified Birch Plywood / Beechwood / Rubberwood | ISO 9001 (Material Traceability) |

| Tire Material | Solid Rubber (Non-pneumatic) | Phthalate-free, EN 71-3 Compliant |

| Overall Dimensions (L x W x H) | 55-70 cm x 30-40 cm x 45-55 cm | Ergonomic Design for Ages 1-3 |

| Seat Height | 22-28 cm (Adjustable options available) | ASTM F963 Clearance |

| Product Weight | 2.5 - 4.0 kg | Lightweight for portability |

| Max Load Capacity | Up to 25 kg (55 lbs) | EN 71-1, EN 71-8 Stability |

| Surface Finish | Non-toxic, Water-based Paint/Varnish | EN 71-3 (Chemical Safety), REACH Compliant |

| Certifications | CE, EN 71, ASTM F963, CPSIA | International Toy Safety Standards |

These specifications underscore the commitment to safety and quality, making these tricycles suitable for diverse environments, from home use to high-traffic educational settings. The robust design ensures minimal maintenance and a long operational lifespan, offering excellent value for B2B procurement. Variants like the two seat tricycle kids or a tricycle stroller for kids will have adjusted dimensions and load capacities.

Application Scenarios and Technical Advantages

The versatility and inherent qualities of a wooden tricycle for kids make it suitable for a wide array of application scenarios, extending beyond traditional home use. Its design principles offer distinct technical advantages over plastic or metal alternatives.

Key Application Scenarios:

- Early Childhood Education Centers: Nurseries, preschools, and kindergartens benefit from the durable and safe design, promoting gross motor skill development and imaginative play. The non-toxic nature is paramount in these environments.

- Retail Markets: High-end toy stores, boutique children's shops, and eco-conscious retailers can effectively market these tricycles to discerning parents who value sustainability and quality. The tricycle for kids with price point often reflects its premium craftsmanship.

- Therapeutic Settings: Pediatric therapy clinics utilize wooden tricycles for developing balance, coordination, and strength in children with specific developmental needs. Adjustable seat heights and robust stability are crucial here.

- Hospitality and Leisure: Family-friendly resorts, hotels, and entertainment venues can offer these tricycles as part of their children's activity programs, enhancing guest experience with safe, engaging play options.

Technical Advantages:

- Superior Durability: Solid wood construction and multi-ply birch plywood offer exceptional resistance to impacts and daily wear, outperforming many plastic alternatives in terms of longevity. The material's natural resilience contributes to an extended service life.

- Enhanced Safety Profile: Natural wood, when properly treated and finished, presents fewer sharp edges and reduces the risk of chemical exposure compared to certain plastics. Recessed hardware and non-slip rubber tires further enhance safety. Compliance with rigorous standards like EN 71 and ASTM F963 is a testament to this.

- Sustainable and Eco-friendly: Sourced from FSC-certified forests, wooden tricycles are biodegradable and have a lower carbon footprint during manufacturing. This aligns with global sustainability initiatives and consumer preferences for environmentally responsible products.

- Aesthetic and Sensory Benefits: The natural grain and warmth of wood provide a tactile and visually appealing experience that synthetic materials cannot replicate. This contributes to a calming and natural play environment, beneficial for child development.

- Low Maintenance: The robust nature of the material and protective finishes mean these tricycles require minimal maintenance, primarily routine cleaning, reducing total cost of ownership for institutional buyers.

Vendor Comparison: Evaluating Wooden Tricycle Manufacturers

Selecting the right manufacturer for a wooden tricycle for kids involves a comprehensive evaluation of factors beyond just unit cost. Quality, compliance, customization capabilities, and after-sales support are paramount for B2B buyers.

Comparative Analysis of Key Vendor Attributes

| Attribute | Premium Manufacturer (e.g., GorgeousBike Co.) | Standard Manufacturer | Budget Manufacturer |

|---|---|---|---|

| Material Quality | FSC-certified Birch/Beech; Grade A+ plywood; Non-toxic, lead-free finishes. | Standard plywood; Water-based paints (may lack specific certifications). | Unspecified wood/plywood origin; Basic finishes; Potential for inconsistent quality. |

| Manufacturing Process | Advanced CNC machining; Multi-stage sanding; Precise assembly; ISO 9001. | Standard machining; Manual finishing; Basic QC. | Basic cutting; Minimal finishing; Limited QC checks. |

| Certifications | CE, EN 71, ASTM F963, CPSIA, FSC. | May have some local certifications; Inconsistent international compliance. | Few to no reliable certifications. |

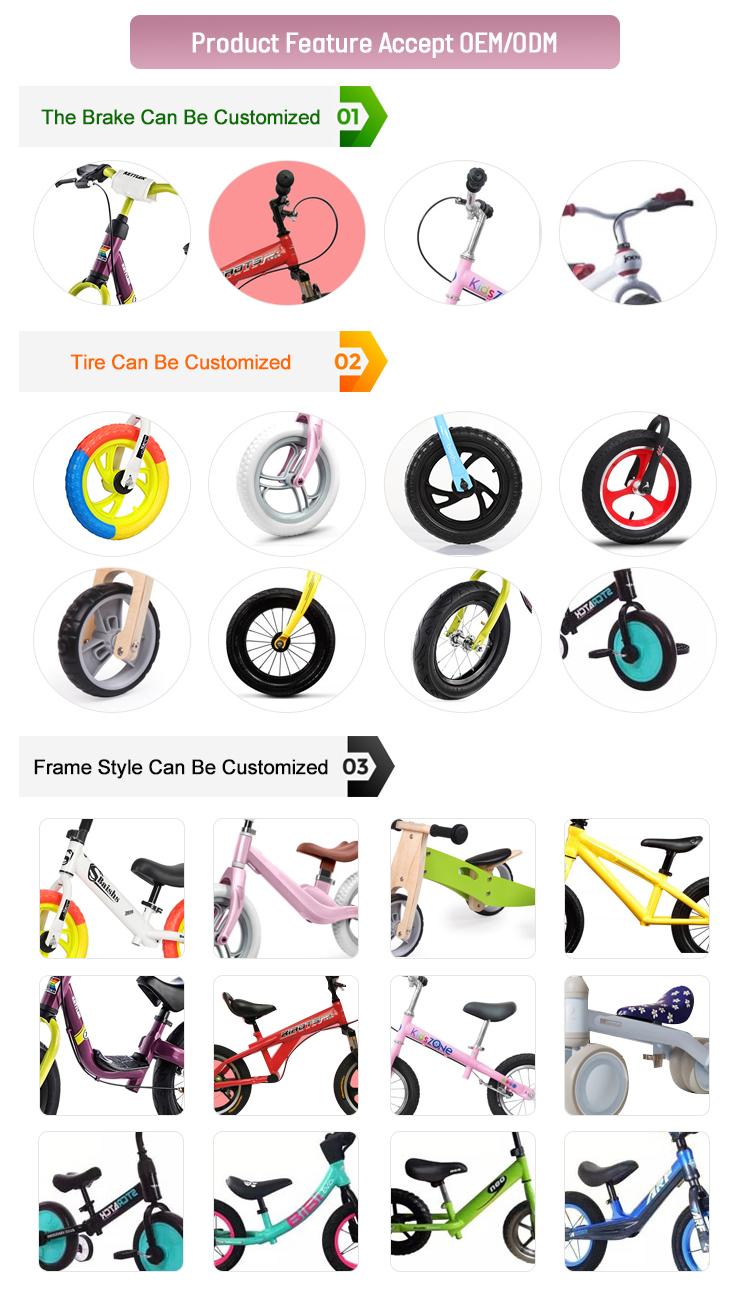

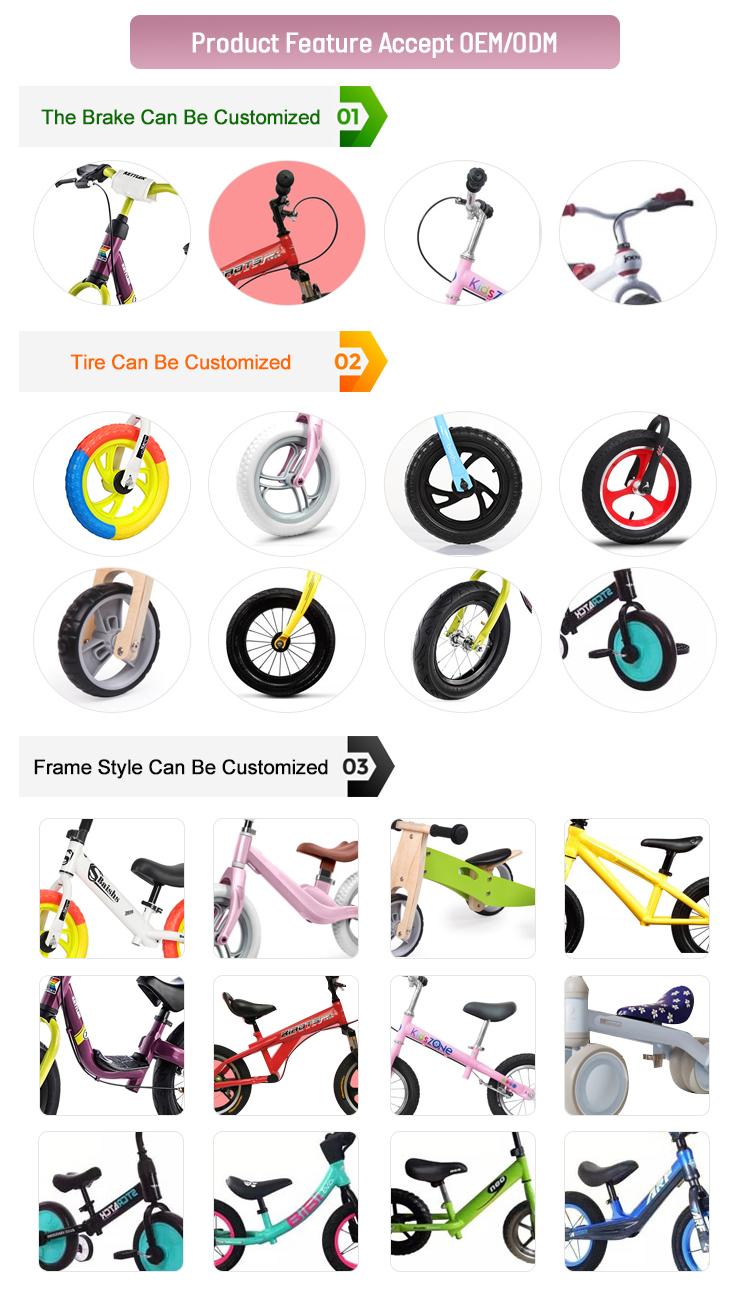

| Customization Options | Extensive: Logo branding, color matching, design modifications, material options. | Limited: Basic color changes, simple logo prints. | Minimal or none. |

| Warranty & Support | 2-5 year structural warranty; Dedicated B2B support; Spare parts availability. | 1-year limited warranty; Basic customer service. | Minimal or no warranty/support. |

| Typical Lead Time | 4-8 weeks (standard orders) | 6-10 weeks | Variable, often longer due to inefficiencies. |

This comparison highlights the importance of partnering with manufacturers who prioritize quality control, robust certifications, and comprehensive support. For specialist products like a tricycle scooters for kids or a tricycle John Deere kids themed product, the customization and design capabilities of a premium manufacturer become even more critical.

Customized Solutions and Application Case Studies

Beyond standard offerings, many B2B clients require customized solutions to meet unique brand requirements, market demands, or specific regulatory landscapes, especially for a wooden tricycle for kids that needs to stand out. Manufacturers who excel in customization can offer significant competitive advantages.

Customization Capabilities:

- Branding and Aesthetics: Custom logo engraving or printing, bespoke color palettes, and unique finishes (e.g., natural wood oil, specific stain colors).

- Structural Modifications: Adjustments to seat height ranges, frame dimensions, addition of backrests for younger children, or integration of elements for a tricycle stroller for kids configuration.

- Material Alternatives: Sourcing specific wood types based on regional availability or ecological certifications, or integrating alternative components like bio-plastics for specific non-structural parts.

- Packaging and Kitting: Custom retail-ready packaging, assembly instructions tailored to different languages, or kitting with supplementary accessories.

Application Case Studies:

Case Study 1: Montessori School Chain, UK

Challenge: A prominent Montessori school chain in the tricycle for kids uk market required durable, aesthetically harmonious tricycles that met stringent UK safety standards (BS EN 71) and aligned with their natural play philosophy. They needed tricycles that could withstand high-frequency use by multiple age groups.

Solution: We provided a custom order of 50 wooden tricycles crafted from Baltic Birch plywood, finished with a natural, uncolored, water-based lacquer. Key modifications included reinforced axles for enhanced durability and slightly wider wheelbases for improved stability for beginner riders. Each tricycle was branded with the school's subtle engraved logo. Lead time was 7 weeks, inclusive of sampling and production.

Outcome: The tricycles integrated seamlessly into the school's play areas. Feedback highlighted their robustness, ease of maintenance, and the positive sensory experience for children. The client reported a significant reduction in replacement costs compared to their previous plastic models, and the natural aesthetic enhanced their educational environment.

Case Study 2: Boutique Online Retailer, USA

Challenge: An online retailer specializing in unique, sustainable children's products sought a distinctive two seats kids tricycle model that complied with CPSIA regulations. They needed a design that reflected their brand's premium, artisanal image and offered a competitive edge in the crowded US market.

Solution: We collaborated on designing a tandem wooden tricycle with an elongated frame and two adjustable seats, allowing siblings to ride together. The design featured integrated storage space for toys and a choice of two muted, lead-free pastel color options. Full ASTM F963 and CPSIA testing was conducted on the final product. The initial order for 300 units was fulfilled within 9 weeks.

Outcome: The custom two seat tricycle kids model became a bestseller for the retailer, praised for its innovative design, build quality, and safety. Customer feedback highlighted the joy of dual ridership and the product's natural appeal. The retailer successfully expanded its market share for unique children's outdoor play equipment.

Frequently Asked Questions (FAQ)

-

Q: What age range are your wooden tricycles designed for?

A: Our standard wooden tricycles are typically suitable for children aged 12 months to 3 years. We also offer models for tricycle for older kids, specifically designed for children up to 5-6 years, with higher weight limits and adjustable features.

-

Q: What safety certifications do your products hold?

A: All our wooden tricycles comply with international safety standards including CE (European conformity), EN 71 (European Toy Safety Directive), ASTM F963 (US Standard Consumer Safety Specification for Toy Safety), and CPSIA (Consumer Product Safety Improvement Act). We also adhere to ISO 9001 for quality management.

-

Q: Can we customize the design or branding of the tricycles?

A: Yes, we offer extensive customization options, including custom color finishes, engraved or printed logos, design modifications (e.g., a two seats kids tricycle, storage compartments), and special packaging. Our design team works closely with B2B clients to bring their vision to life.

-

Q: What is the estimated lead time for bulk orders?

A: For standard bulk orders (e.g., 100-500 units), the typical lead time is 4-6 weeks from order confirmation and deposit. Customized or larger orders may require 7-10 weeks, depending on complexity and material sourcing. We maintain transparent communication throughout the production process.

-

Q: What warranty do you offer on your wooden tricycles?

A: We provide a 2-year structural warranty against manufacturing defects under normal use. This covers the integrity of the wooden frame and major components. Specific details are outlined in our B2B purchase agreements.

Lead Time, Fulfillment, and Support Commitments

Our commitment to B2B partners extends beyond product quality to encompass efficient logistics and comprehensive post-sales support, ensuring a seamless procurement experience for every wooden tricycle for kids order.

Lead Time and Fulfillment Process:

- Order Confirmation: Upon receipt of a confirmed purchase order and initial deposit (typically 30%), production scheduling commences immediately.

- Production Phase: Standard orders for our wooden tricycles generally have a production lead time of 4-6 weeks. This includes material preparation, CNC machining, finishing, assembly, and rigorous quality checks. Customized orders may extend to 7-10 weeks, depending on the complexity of design modifications and sourcing of specialized materials.

- Quality Assurance: Throughout production, batch testing and individual item inspections are conducted. A final comprehensive Quality Control (QC) check is performed before packaging.

- Packaging and Shipping: Products are packaged securely for international transit, meeting industry standards to prevent damage. We coordinate with reputable logistics partners for efficient global shipping, offering EXW, FOB, and CIF terms as per client requirements.

- Final Payment & Dispatch: Balance payment is required upon completion of production and final QC approval, prior to dispatch from our facility.

Warranty and After-Sales Support:

- Structural Warranty: We offer a 2-year limited warranty on the wooden frame and major structural components against manufacturing defects under normal use. This warranty underscores our confidence in the durability and quality of our products.

- Parts Replacement: In the event of a covered defect, we commit to providing necessary replacement parts or product exchanges. Minor wear-and-tear items (e.g., tires after extensive use) are typically available for purchase.

- Dedicated Customer Support: Our B2B clients receive dedicated account management and technical support. Our team is available to assist with product inquiries, troubleshooting, warranty claims, and reordering.

- Documentation and Resources: We provide comprehensive documentation, including assembly instructions, safety guidelines, and product specifications, in multiple languages as required for international distribution.

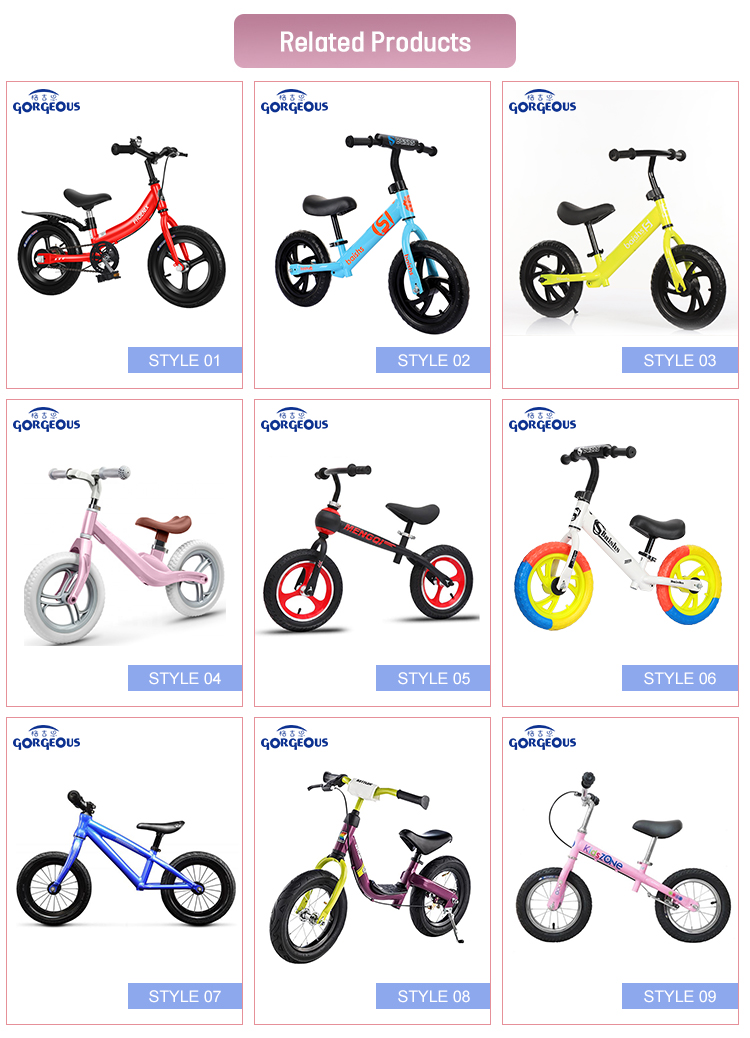

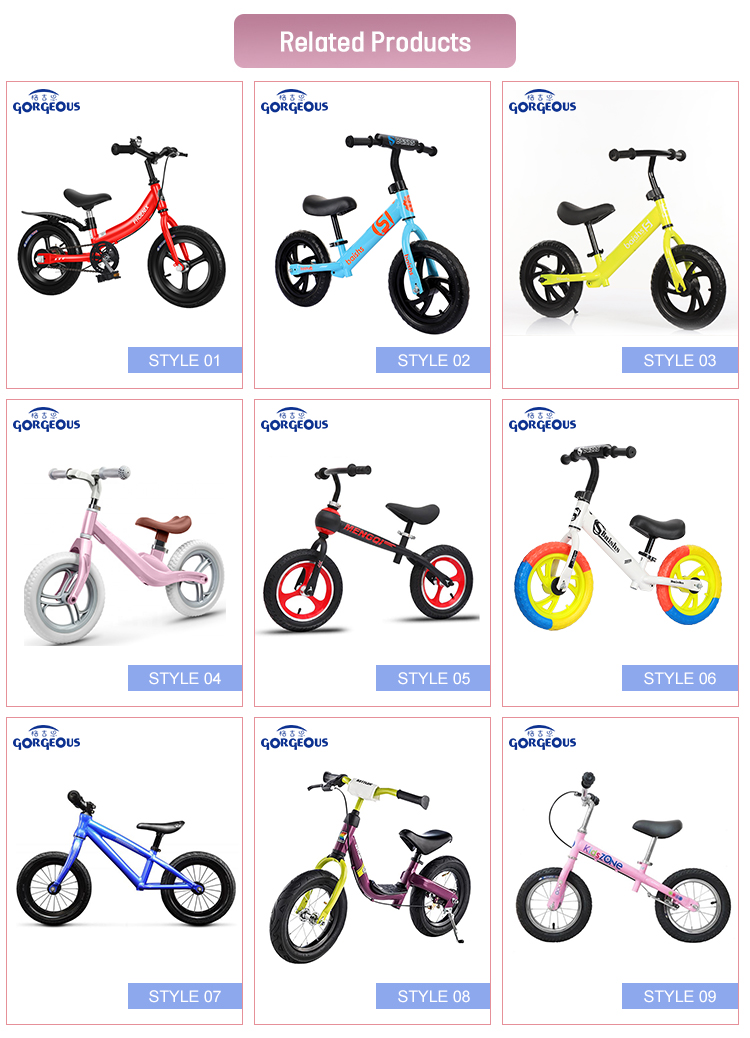

Additional Images

References

- European Committee for Standardization. EN 71 Safety of toys. Brussels, Belgium.

- ASTM International. ASTM F963: Standard Consumer Safety Specification for Toy Safety. West Conshohocken, PA.

- Forest Stewardship Council (FSC). Principles and Criteria for Forest Stewardship. Bonn, Germany.

- International Organization for Standardization. ISO 9001: Quality management systems – Requirements. Geneva, Switzerland.

- U.S. Consumer Product Safety Commission (CPSC). Consumer Product Safety Improvement Act (CPSIA). Washington, D.C.

-

The Essential Guide to 16 Inch Child's Bikes – Safety, Specs & Trends

NewsNov.24,2025

-

Kids Road Bike 24 – Lightweight, Safe, and Perfect for Young Cyclists

NewsNov.23,2025

-

Discover Safe and Fun Children's Bikes 14 Inch | Durable Kids' Bikes Reviewed

NewsNov.22,2025

-

Discover the Perfect Little Girl 16 Inch Bike – Safety, Style & Performance

NewsNov.22,2025

-

The Ultimate Guide to 12 Kids Bicycles – Safety, Trends & Top Picks

NewsNov.21,2025

-

14 Inch Children’s Bikes: A Guide to Safety, Durability & Global Impact

NewsNov.20,2025